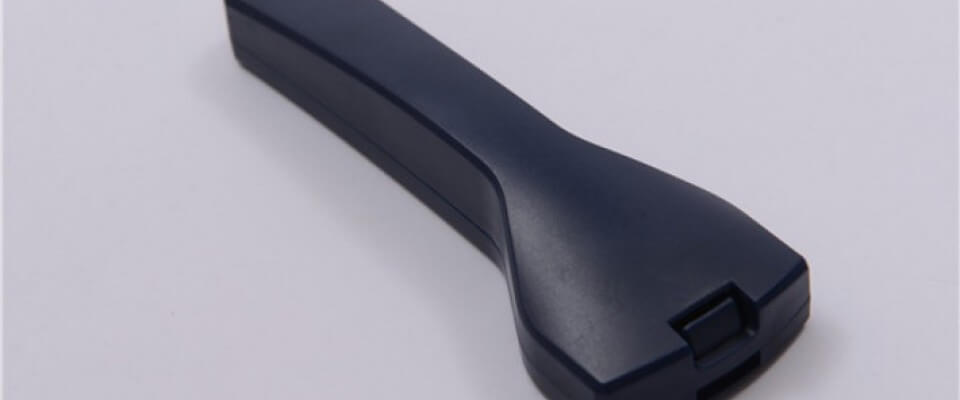

low-volume production of Injection molding and Prototype Molds

The injection molding Low Volume Manufacturing or Rapid Manufacturing method applies to all industries that make plastic parts by injection molding. The technology can be used to minimize the molding time for your products, to produce pre-mass quantities with real material, or to produce small quantities of finished products. Molding costs of low volume production are significantly lower than those of conventional methods.

Topworks offering low volume production

We offer injection molding low-volume manufacturing services, providing our clients with the ability to manufacture hundreds of thousands of plastic parts so that their products can be brought to market.

Perhaps our prototyping services would be of benefit to you if you only need a few parts or prototypes. Throughout the prototyping and production process, we at Topworks are by your side.

We encourage you to contact our team once you are ready to begin your next project and upload your 3D CAD files for a free quote.

-

Injection Molding Low Volume Manufacturing: What Is It?

Depending on the manufacturing method, low-volume injection molded products can be production-quality parts in smaller quantities, usually less than 2,000 unique pieces.

It's a popular approach for many products, since it enables a rapid product development cycle, offers a fast route from early prototypes to mass production, as well as reducing tooling and material investment.

-

Why Low Volume Manufacturing Is Better

What are the ways that low-volume manufacturing can benefit your business? To name a few:

- Build a link between prototyping and mass production

- Low minimums to reduce costs

- Connect emerging markets quickly

- Shorten product lifecycles quickly

- Streamline the design process

- Prevent many hidden problems

-

Prototype Molds

In order to evaluate the aesthetics and function of a newly designed product, prototype molds are needed to make samples of the new product. Tests on molded samples are more accurate than those on hand-made (machined or assembled) samples.

Furthermore, it may produce a more accurate result (and be less expensive) than a computer simulation. Taking shortcuts everywhere is possible, as long as the material used to construct the mold is sufficiently strong and can withstand the heat and pressure of the plastic injection. This applies to mold materials such as mild steel, aluminum, even plastic (epoxy, etc.).

It is usually unnecessary to maintain close tolerances. Surface appearance (polishing, engraving, even flashing) won't be an issue in general. As long as the plastic has cooled enough, the molded sample can be removed from the mold without cooling channels.

Additionally, ejector mechanisms are not always necessary. There may be no need for more sophisticated ejector pins than one or two air jets directed at the edge of the product at the parting line. For example, loose inserts in the mold can be used to produce threads in the product, which are then ejected with the finished product and unscrewed by hand.

Also, loose inserts can be used in areas that would otherwise require side cores, such as on the sides of a product.

Once the molded piece is cool, it can be machined with rounds or simple openings. This is merely a sample of the mold features that can be eliminated to simplify stacks and to lower the cost of prototype molds.

It is also possible to mount prototypes in a mold shoe, saving even more money if prototypes are frequently needed. An edge gate might consist of sprue and a short runner or a simple sprue gate directly into the product. A manual cut will then be performed on the gate.

https://www.plasticmoulds.net/low-volume-production

Comments

Post a Comment