Injection Molding Material Drying

Injection Molding Material Drying

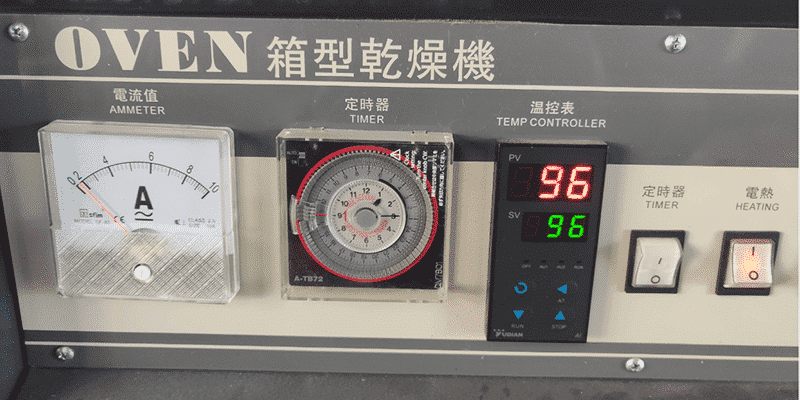

oven

In some materials, moisture can be absorbed by them from the atmosphere, which can cause the material to hygroscopic. When relatively damp materials are injected into a mould, they become splashed, splayed, or cast with mica marks due to steam bubbles and other volatiles disintegrating as the melt flows upon it.

When exposed to very low moisture content, some materials suffer embrittlement, such as polycarbonate or the thermoplastic polyesters. It is essential to thoroughly dry these materials before moulding.

Drying times may need to be extended when conditions are adverse (for example, if the material is exceptionally moist or the drying equipment is not efficient).

To minimize the risk of degrading nylon products, this material should be dried in a vacuum oven to prevent possible discoloration and embrittlement caused by oxygen in the air.

A dehumidifier should be used before running air circulating ovens or dryers.

However, some materials in theory that should be dried can be used right from the container. Buying them in undamaged sealed containers from a reliable supplier and using them quickly in a moulding shop with low humidity is the only way that they will last, though. Ask the material manufacturer for advice if you are unsure about drying requirements.

It is sometimes necessary to dry some filled polymers prior to molding them because they are normally incapable of absorbing water.

The vented barrel machine may be sufficient for materials such as ABS and acrylics that do not require drying.

A wide range of thermoplastics is shown in Table below, along with the appropriate drying temperatures and times.

To ensure that your dryer performs as expected, it is important to maintain it properly. In addition, the type of dryer required depends on the resin you are processing and whether you are drying at high levels (228° - 300° F) or low levels (below 220° F). In order to ensure that the performance of the dryer meets the requirements of the resins you are processing, you should take into consideration these factors.

Keep track of your Dew Point

Dew points are not directly correlated to the degree of dryness of the resin, but rather to the level of dryness of the air the dryer produces. Knowing the dew point, however, can help you determine if the dryer is working at optimal levels. To determine if the dryer is up to the job, it must continuously measure the dew point.

Keep an eye on air flow

A good air flow is vital. It serves both as a vehicle for providing low dew point air to dry the resin and as a means for transporting heat from the process heater to the resin. In order to prevent air flow reductions, a continuous monitoring device - mainly a pressure drop device - should be used.

Make sure air filters are clean

Both those used in the process and those used in the regeneration. Keep an extra set of clean filters on hand at all times (every two weeks). Cleaning and changing the filters is never convenient, but operating the dryer without filters can lead to plastic dust getting into the heater and causing a fire or damaging the desiccant.

Maintain Molecular Sieve Desiccant Temperature

Low temperature is most conducive to evaporating moisture from air. In the case of air temperatures exceeding 145-155°F, the dew point will not reach -45°F/C. Whenever the return air temperature exceeds this level, too much processing air is being used. Temperature indicators, such as thermocouples, will allow you to determine this. Depending on the temperature, some modern systems can control airflow automatically via a variable frequency drive (VFD). It is also essential to maintain return air temperatures between 145 and 155° F to minimize energy consumption.

Drying at low temperatures can be dangerous

Most standard dryers cannot achieve temperatures below 165-175 F. Many nylons, polymers, polylactic acid, and PLA can withstand these temperatures. Even though the dryer's return temperature is 145-155 F, another rise in temperature occurs as the air passes through the blower and one again as the air passes through the desiccant. When using desiccant drying, an additional post-dryer cooling coil is usually required. In addition, twin tower dryers find it difficult to achieve this as well.

When the towers switch, the temperature spikes as the newly regenerated partially cooled bed comes on. The membrane type dryer is another option for low temperature resins that can reach low temperatures with minimal water used. Throughput is limited to approximately 210 pounds per hour.

Precautions for High Temperature Drying

When resins are dried at temperatures higher than typically 225 F, a cooling coil with tower water should be present at the end of the hopper. In addition to the water saving valve, this may also incorporate a heat pump. Remember, over-cooling (below 135F) will leave the process air heater and cooling water system under more load if the air in the cooling coil is under-cooled.

Desiccant must not contain volatiles

Volatiles (organics) are liable to come off of resins during drying. Over time, resins like PET, nylon, PBT, and some others can release significant amounts of these contaminants, contaminating and damaging desiccant. Carbon dust, a by-product of this contamination, may enter the drying hopper and cause resin contamination. Any system that contains volatiles needs to be equipped with a proper plasticizer system.

Make sure the resin is dry enough

The moisture level of the resin is not dependent on only the -45° dew point of the dryer. For best results, verify the resin leaving the drying hopper has met the process requirements with an on-line or off-line measurement tool. The products can have flaws once they are under-dried. On the other hand, over-drying can make some products brittle. You can only tell if the resins you send to the process have been properly treated by measuring their moisture content.

It is important to inspect your desiccant

Molecular Sieve beads, Silica Gel beads, and Pure Crystalline Molecular Sieve are the types of desiccant normally used in plastics industry dryers. When they work properly, molecular beads provide -45°dew point drying air and are common in twin bed dryers. The clay content of these desiccant cylinders makes them less effective than pure crystalline desiccant and they need to be replaced after two years. Check it by checking it for discoloration - replace it if it is. A handful should feel warm if you squeeze it quickly. In this case, replace it. It is typically used as a desiccated blanket on top of silos since silica gel does not produce -40° dew point air. Desiccant wheel dryers use pure crystallinity molecular sieve. Several years ago, it produced consistent dew points below -45°.

Be on the lookout for leaks

Anything that leaks out of a closed loop is problematic. Make sure you regularly check your system for problems. "Closed loops" are usually filled with ambient air that has a high moisture content. When the desiccant must be heated further to remove excess moisture due to air leaks, power bills can increase significantly.

Keep an eye on warnings

Many dryer controls have warning lights that come on when something goes wrong. Some controls will simply give a warning, whereas others will tell the operator what the problem is as well as what needs to be done to resolve it. It is either correction is necessary or there will be greater consequences if no action is taken. Turning off the warning after acknowledging the warning is not the correct way to respond.

It is important to follow these simple tips to help run a more efficient production line with fewer emergencies. Plus, that leads to more productivity and a higher profit margin.

https://bit.ly/3jG0SJb

Comments

Post a Comment