Types of Plastic Moulding How to Choose the Right Type!

Does this sound familiar? You've launched a new product! Things have been going well and your business has reached the point where you need to hire a professional designer. This means it's time to prepare your product design guidelines.

But how do you get started on this process? There are plenty of factors that you consider as a designer and here we will outline 5 types of plastic moulding that every designer should know.

1. Injection Moulding

Injection moulding is the process of manufacturing plastic parts with a mould. This is accomplished by injecting melted polymer into a mould that replicates the shape of the finished part. The mould is usually made from tool steel, which can withstand the high temperatures of the molten polymer.

The most common materials processed by injection moulding are thermoplastics, including polyacetal (POM), nylon, polycarbonate (PC), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and high impact styrene acrylonitrile (HIPS).

Injection moulding is the process of manufacturing plastic parts with a mould. This is accomplished by injecting melted polymer into a mould that replicates the shape of the finished part. The mould is usually made from tool steel, which can withstand the high temperatures of the molten polymer.

The most common materials processed by injection moulding are thermoplastics, including polyacetal (POM), nylon, polycarbonate (PC), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and high impact styrene acrylonitrile (HIPS).

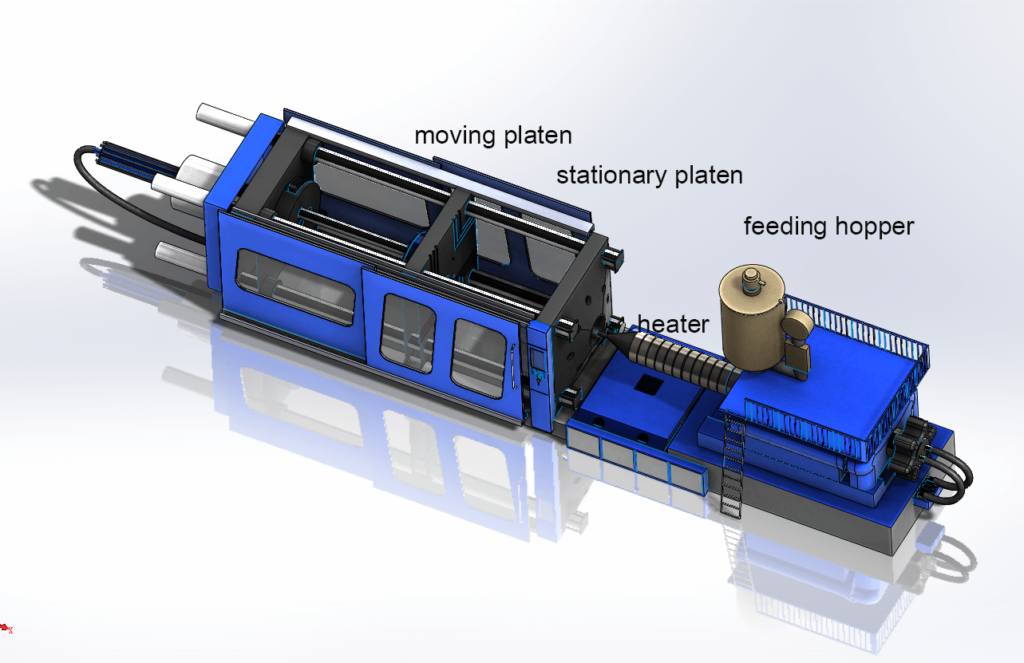

Injection Moulding Process

The Injection Moulding Process involves placing raw materials into a hopper and melting their consistency in a heating chamber called a heater barrel. The melted plastic then passes through an injection unit where it is forced into the mould cavity under pressure from a hydraulic ram called an actuator. The ram pulls back once the plastic has been injected into the cavity, ejecting any excess material left in the nozzle. Once cooled down and solidified, the finished product is ejected from its mould by an ejector pin or punch mechanism that pushes the mould open and releases the part.

The main advantage to this type of manufacturing system is that it allows for fast production rates while using relatively low energy consumption levels due to its high production volume per cycle time period.

2. blow moulding

Plastic blow moulding is used for the production of large hollow or hollow-bodied products with a large connecting surface area between the inside and outside walls of a part.

Blow moulding is used to produce bottles and other containers. The process starts with an airtight preform made of either raw plastic or glass. The preform has a hollow cavity that is filled with molten material, which cools and solidifies to form a bottle or other container. The preform is then heated until it loses its shape, which allows it to be removed from the hollow cavity. The preform is replaced by another one, and the process continues until all the cavities have been filled.

In blow moulding, a pre-heated blow mould is placed over the plastic pellet. The pellet melts and flows into the mould cavity where it cools and hardens into its final shape. The blow mould is then opened, revealing the finished product.

The process of blow moulding has many advantages:

It's one of the most affordable manufacturing processes available, making it ideal for high-volume runs.

It can produce very large products, including items that are too big to fit in other types of machines (like bottles). The process can also be used to make complex shapes like sports balls or toys with moving parts.

3. Extrusion moulding

Extrusion moulding is a plastic processing method that uses a material to push through a die in order to create a consistent final product. The type of material used depends on the end result, but many extrusion processes use molten thermoplastics.

In this process, a solid or semi-solid plastic is forced through an opening called the die. This creates a hollow tube of plastic that can be cut into different lengths or shaped into various shapes.

Extrusion moulding has many advantages over other methods of plastic processing, including:

Consistency

this method produces consistent results because it uses the same amount of pressure and speed for each part. It also ensures that all parts are exactly the same size and shape as one another.

Low cost

because extrusion requires less labour than other forms of plastic processing, it can be done quickly and cheaply. This makes it ideal for mass production environments where large volumes of parts are needed quickly and cheaply .

Versatility

extrusion can be used to create a variety of shapes and sizes, including: pipes, rods, bars, tubes and sheets. This makes it flexible enough to produce a wide range of products.

Durability

because extruded plastic is hard and rigid, it can be used in applications where strength is important. This makes it a good choice for components that will be subject to stress or impact, such as: handles, hinges and brackets.

4. Compression moulding

Compression moulding is a manufacturing process in which two or more materials are heated and pressed together to form one solid mass. The process is similar to injection moulding except that compression moulding involves an upper die with a cavity and a lower platen.

The upper die is typically made of steel, while the lower platen is made of either steel or aluminum. The upper die and lower platen are heated and forced together, which causes the molten plastic material to be squeezed out between them. This creates a uniform thickness of material between the two dies.

The plastic resin is injected into the die cavity as it's being compressed by the upper die and lower platen. This process produces high pressure at every point on the plastic resin surface, yielding a strong finished product with few air bubbles inside it.

5. Rotational moulding

Rotational moulding is a manufacturing process that uses an array of hollow plastic molds to create objects by injecting heated plastic into the mold. These molds are mounted onto a rotating platform, which turns in order for the item to be formed.

The plastic used in rotational moulding is usually a mixture of polymers and other additives, such as colorants or other materials that make it more durable or flexible. A wide range of products can be made using this method, including toys, medical equipment and even car parts.

Rotational molding is used by companies across a wide range of industries, including those that manufacture plastic containers, such as shampoo bottles. The technique has been around since the 1960s, when it replaced injection molding as the preferred method of creating products from plastic.

takeaway

Knowing what type of plastic to work with can make all the difference between a successful project and a failed one. Knowing more about the different types of plastic that can be used for various projects, then, is helpful for designers and engineers of all stripes. And with so many options available, whether it's in the form of resin or non-resin products, it helps to know what the differences are between each option and how to decide which one will be right for your needs.

https://www.plasticmoulds.net/types-of-plastic-moulding-how-to-choose-the-right-type.html?feed_id=764&_unique_id=634f72c439e6d

Comments

Post a Comment