Custom Unscrew Injection Molds

Unscrew injection mold is used to produce products with internal thread. Threaded parts are widely used in automobiles, motorcycles, bicycles, electrical appliances and other fields.

Unscrew Injection Molding process

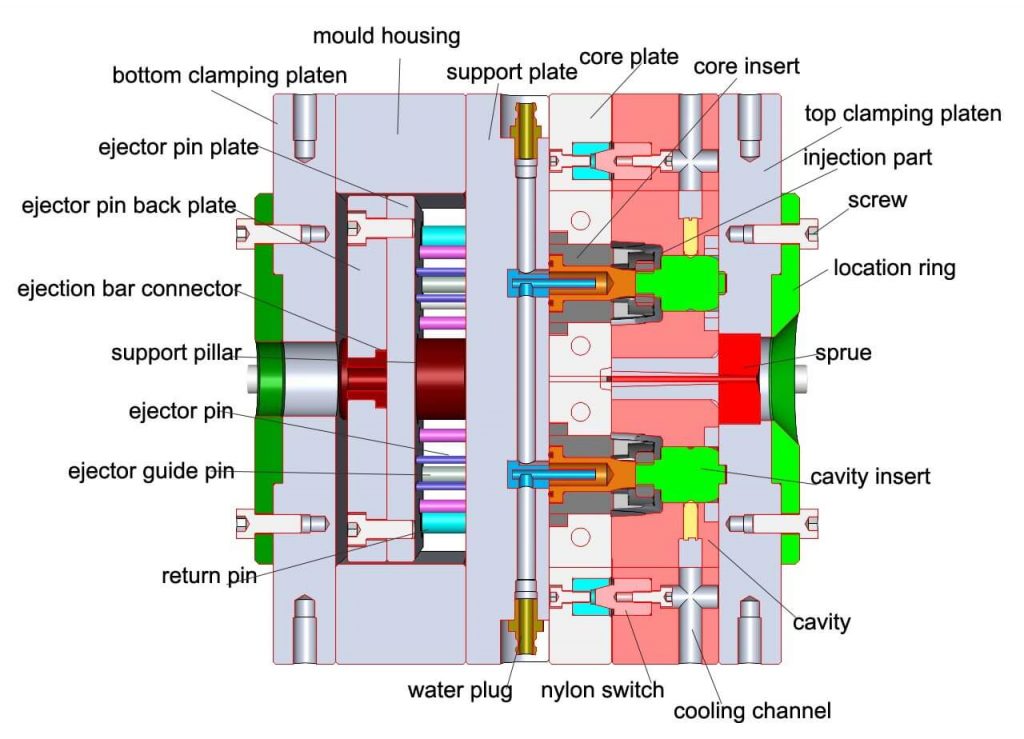

Unscrewing mould usually consists of at least 2 different cores, one for core and cavity, the other for unscrewing.

-Molten plastic is injected into a steel mold to begin the process. Injecting plastic into the tool is the first step. After the plastic has cooled, the threaded core can be unscrewed. A hydraulic cylinder drives the rack-and-pinion unscrewing mechanism.

-The rack turns three gears, which then retracts the threaded core back.Using a rack to move a core out of the mold is called "reverse-acting." In this case, it allows the core to be pulled out of the mold rather than pushing into it.

-The ejector system automatically pushes a stripper plate forward upon injected parts disengaging the threaded core.

-It is then reversed by the hydraulic cylinder in order to reposition the threaded core, and the molding process is repeated.

This process can be used for both high volume production runs and low-volume production runs. It is also possible to have multiple cavities on one machine, which allows for greater productivity and lower cost per unit.

Unscrew Injection Molds: screw size

The screw size is measured by its pitch and diameter. A pitch refers to the distance between turns of a screw and diameter refers to its length. For example, if you have a 1/4" long screw with a diameter of 0.125", then it has 4 threads per inch (TPI). Some unscrewing molds require large screws while others require small screws but they all depend on the size of your product and how fast or slow you want it to be injected into your mold cavity.

If you want to design a long screw type injection mold, there are certain things that you need to consider:

- Screw length – This should not exceed 5 times the diameter of your barrel because adding more than this will cause unnecessary friction which can affect the quality of your products

- Screw pitch – This refers to how far apart each thread section is from each other and usually ranges from 1:1 up to 6:1 depending on how much pressure needs to be applied for your product

A complicated mold

Unscrew injection mold requires more precision than normal injection molds. Unscrew injection molding machines have a lot of moving parts, so they need to be handled with care in order to avoid damage or malfunctioning.

In order to ensure that an unscrew injection mold works properly, you should always keep an eye on your equipment and make sure that all parts are working properly. If any part of your unscrew injection mold begins to malfunction, it may cause problems with your finished product such as poor fitting or cracks in plastic parts.

The unscrewing motion of the tool is a critical operation of the injection molding cycle, which directly affects the product quality and performance. At present, there are many methods of controlling the unscrewing motion, such as using springs, hydraulic systems and electric motors. Using hydraulic systems or electric motors to control the unscrewing motion has some disadvantages such as high cost, high power consumption and low reliability. So it is necessary to use other methods to control the unscrewing motion of molds.

https://www.plasticmoulds.net/custom-unscrew-injection-molds.html?feed_id=744&_unique_id=63478e0c26e6b

Comments

Post a Comment