Tips for Choosing a Reliable China Injection Molding Supplier

Tips for Choosing a Reliable China Injection Molding Supplier

What Is Injection Molding

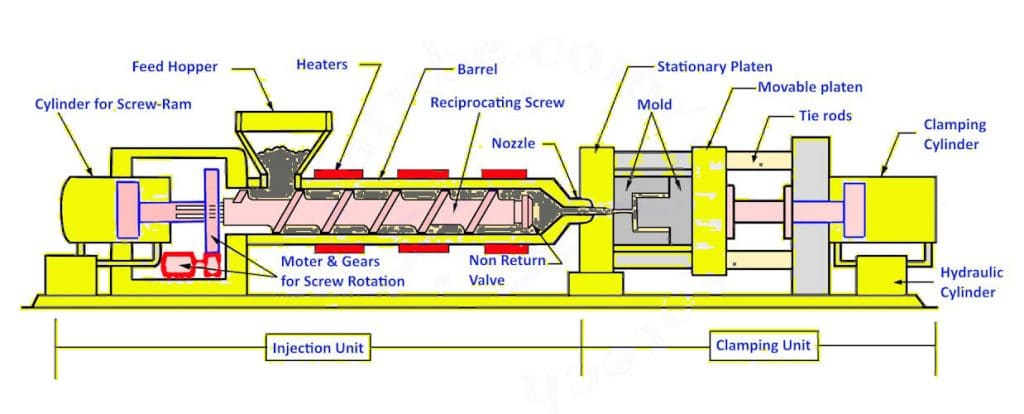

An injection molding process involves the injection of molten material into a mold and then allowing the material to cool, resulting in a solid shape. It is possible to manufacture a wide range of objects using injection molding, including automobile parts, toys, and medical devices.

1.Melting

The heated barrel and rotating screw is fed with material from the hopper.

By heat, friction, and shear force, the material melted by the rotation of the screw is forced through a check valve to the front.

2.Injection

The screw is forced forward from the back end by a hydraulic ram after having been moved forward by the shot of material at the front.

3.Cooling

The tool remains closed until the plastic has completely cooled and hardened in the mould tool cavity. This is usually the longest portion of the injection moulding process.

4.Ejection

The next moulding is performed by back-moving the screw. The tool opens and the plastic part is ejected. Next, the tool closes, and the injection molding process is repeated at 1.

Material, usually metal or plastic, is melted at the beginning of the process. A high pressure injection is then used to inject the molten material into the mold. It is opened and ejected from the mold when the matter has cooled and solidified. The process of injection molding can be used to produce mass quantities of objects quickly and at a reasonable cost.

An overview of injection molding history

A history of injection molding can be traced back to the 1800s. Alexander Parkes invented a method for molding cellulose into objects in 1851, marking the beginning of injection molding. The first plastic injection molding machine was patented by John Wesley Hyatt in 1872.

As a result of this machine, plastic objects could be mass produced in large quantities. With the advent of mass-production of plastic products in the early 1900s, injection molding became increasingly popular. Medical devices, automotive parts, and electronics are among the types of products manufactured using injection molding today.

Reliable China injection molding Suppliers: Why You Should Choose Them

It is important to select a reliable China injection molding supplier when looking for one. The importance of this can be attributed to a number of factors. , including the financial position of the China injection molding supplier, their experience in the industry and their reputation.Some quality factors to consider when selecting a reliable China injection molding supplier include whether or not they have a factory, what type of quality assurance system they require and how many employees they have.A China injection molding manufacturer with an established factory

You may not be able to obtain high quality injection molding parts if your supplier is not reliable. Customers may become unhappy as a result and sales may be lost. With a reliable and flexible China injection molding supplier, you can win over customers who may be apprehensive about purchasing injection molding parts.

It is also possible that an unreliable injection molding supplier will not be able to deliver your products on time, which could result in sales being lost.The time it takes for the recipient to receive the order.You should ask the plastics supplier about their average time for delivery.

The third disadvantage is that you will have difficulty obtaining assistance from an unreliable supplier if there is a problem with your order.

There are a lot of risks involved in purchasing goods without any protection. You might not receive the item you ordered and the supplier might refuse to give you a refund. If this happens, then it will be hard to find someone who can help you get out of the situation.

Last but not least, working with a reliable injection molding supplier is generally more convenient. You will typically receive better customer service from them, as well as a more rapid response to any issues you may have.

They’ll take into consideration any requests you may have and give the same weight as any other business. they might even be able to secure you a refund in certain circumstances if their error caused you a problem.

Design of components (7 days)

to supply 3D files

Parts Prototyping (if necessary)(2 -3 days)

Or Topworks side

Tool Design(3-7 days)

Topworks side

Tool Check and Mold Flow Analysis(1-2 days)

Tool Fabrication(3-8 weeks,it depends)

First Shots To Client(T1,3-4 days)

Tool Modifications and

Texturing (3-7 days,it depends)

In this stage, the texturing process is done, which is usually the last step before mass production.

Mass Production Run or Export

Finding a potential injection molding supplier in China: How To Do It

Research is crucial when looking for mold manufacturers in China . It is possible to research potential plastic molding suppliers in a few different ways, and each has its own advantages and disadvantages.

Searching online for potential suppliers is one method of researching potential suppliers. By doing so, you will gain a better understanding of what products or services a supplier offers, as well as their pricing. Nevertheless, keep in mind that not all information found on the internet is reliable, and it is important to do your research before making any decisions.

It is also advisable to speak with other businesses who have used potential suppliers in the past to conduct further research. The purpose of this is to provide first-hand information about the quality of the company's products or services, as well as the level of customer service they provide.

Asking Your potential China injection molding suppliers the right questions

When vetting potential China injection molding suppliers, it is critical to ask the right questions, especially if the supplier is based in China. In order to enter into an agreement with a Chinese supplier, the following 4 questions should be asked:

- How long has your company been in plastics business? As a result, you will be able to gain a better understanding of the company's experience and how long it has been in injection molding and tooling business.The company’s website should provide a list of services or products they offer, as well as some examples of customers who have purchased these items.You should also pay attention to whether they focus on international or domestic operations, how long their business has been in operation, the size of their workforce and where they are located.

- How would you describe your main plastic products and services? In order to determine whether the company is a good fit for your needs, you should know what it specializes in. and how it operates .You should also be aware of how long the company has been in business, as this can indicate whether it is trustworthy or not.

- Are there any references you can provide? By speaking with references, you can gain an understanding of both the quality of the injection molded products and services offered by the company. In addition, you can gain an understanding of their level of customer service. and their ability to meet deadlines.

- What is the minimum order quantity (MOQ) for your products?Minimum Order Quantity, or MOQ, is a set number of injection molded units that must be ordered for a certain product to be made. This often prevents companies from taking on small orders and can lead to high costs per unit. Despite this, there are some benefits of MOQs, including the added security of having enough inventory to last an extended period of time.

A supplier contract should include the following features

It is important to look for certain key elements when entering into a supplier contract to ensure that your company is protected. You should be aware of the following:

- Contract scope - The supplier's scope of work should be clearly defined in the contract. As a result, there will be no misunderstandings in the future.

- Pricing - Ensure that the contract clearly states the pricing to avoid surprises down the road.

- Terms of payment - Before signing any contract, make sure you understand the terms of payment. Getting stuck with unexpected costs is not something you want to happen.

- Delivery schedule - Make sure that you and the injection molding supplier are on the same page when it comes to delivery schedules. By doing this, you will be able to avoid any delays in receiving your goods or services.

Tips for building a good relationship with your China supplier

It is essential to build a good relationship with a Chinese injection molding supplier to ensure a successful partnership. Getting started can be easy if you follow these tips:

- Make sure you are clear about your injection parts expectations and needs. It is essential that your supplier understands the specifications and requirements of your product.

- Ensure that you communicate regularly. You and your supplier will be able to build trust if you maintain open communication.

- Respond to their inquiries and requests in a timely manner. Make sure to respond promptly to your supplier's questions or clarifications for plastic mold.

- Keep track of your invoices and pay them on time. This will demonstrate your reliability and trustworthiness to your supplier, as well as help you maintain a good working relationship.

- It is important to provide both positive and negative feedback.

- Respect and understanding are essential when dealing with cultural differences.

With these tips, you can build a good working relationship with your supplier that benefits both of you.

Visiting the China Supplier's Factory

Before placing an order with a new China injection molding supplier, it’s always a good idea to visit their factory. This will give you the opportunity to see the injection molding manufacturing process and meet the people who will be making your products. It’s also a chance to make sure that the factory is up to your standards in terms of cleanliness, safety, and working conditions.

When you visit a China plastic injection molding supplier’s factory, there are a few things you should keep in mind.

First, schedule your visit for during business hours so you can see the factory in action.

Second, dress conservatively and avoid wearing anything that could be considered offensive.

Third, be prepared to negotiate on price and delivery time if you’re not happy with what the supplier is offering.

When visiting a supplier's factory in China, be sure to schedule plenty of time to tour the facility and meet with key personnel. Be prepared for a language barrier, as most workers will not speak English. While on the tour, pay close attention to the cleanliness of the factory and whether or not safety precautions are being followed. Ask questions about the production process and get a feel for how organized and efficient the operation is. Finally, be sure to inspect the products that are being produced to ensure they meet your quality standards. By taking these steps, you can get a good sense of whether or not a particular supplier is right for your company.

Conclusion: The Importance of Choosing a Reliable China Injection Molding Supplier

As the world increasingly turns to China for manufacturing needs, it is more important than ever to choose a reliable supplier. This is especially true when it comes to injection molding, as the process is complex and requires precision. There are many factors to consider when choosing a supplier, such as cost, quality, and delivery time.

It is important to do your research and ask for recommendations when choosing a supplier. You should also visit the facility and meet with the team to get a better understanding of their capabilities. Once you have found a supplier that you trust, it is important to build a good relationship with them. This will ensure that you can count on them for all your future needs.

https://www.plasticmoulds.net/tips-for-choosing-a-reliable-china-injection-molding-supplier.html?feed_id=494&_unique_id=63081388d5aa3

Comments

Post a Comment