![]()

The failure of injection molding projects is all too common. You will learn why projects fail and how to prevent them in this section.

It's happened to all of us. When you get excited about a project, you can't help but spread it. It's exciting to gather a great team, research well, and plan well before injection molding getting started. Unfortunately, things don't always work out as planned. There are missed deadlines. Results are not as expected. Both customers and managers are unhappy. The situation is terrible.

Why is it that projects with so much potential end in failure?

What are the signs that a project is failing?

If the injection molding project doesn't deliver on time and within budget, it is considered a failed project. But, most of the time, the success or failure of a project is decided by its stakeholders. They judge the outcome and are satisfied with it.

A project can also be deemed a failure when it fails to meet the ROI target and/or the financial forecast.

There are many reasons. But the good news? You can conquer each obstacle to make your next project, and every one after that, successful. Learn some injection molding project management basics.

There are many factors that could cause a project to fail. One reason is that there are changes in organizational priorities. Also common is a change of project objectives, unclear risk definition and poor communication. Kissflow Project helps you to stay on top of your project and avoid failure.

How to prevent injection molding projects from failing!

Here's how to avoid project disaster.

1. Resource planning is lacking

1. Resource planning is lacking

Timing is important to us. Meetings are planned. Topics and interfaces are planned. Unfortunately, we often forget to plan for our resources. Many projects fail because of this. Managing resources is essential to managing projects. Taking into account other projects may be part of this process. Financial resource planning is important for many businesses.

If you are searching for

injection molding resources for your next job, here are a few questions to ask.

Will there be a need for human resources? For how long and who? Could any of them be called to work before my project is completed if they are working on another project?

How much space will be needed? To make this project successful, do we have the right office space, computers, and meeting areas?

Which vendors from outside can we rely on? How quickly can they turn around their

work?

Do we have any knowledge gaps? Could you provide training or bring in an expert?

2. Uncertain Goals & Objectives

If you do not have clear goals or objectives for your injection molding project, it is almost certain that it will fail. If you don't know what you're trying for, it is almost impossible to determine if you succeeded.

Consider a simple personal example. Let's take an example: You have decided to "get in form." What does that actually mean?

Do you want to lose weight?

Building muscle?

You can build endurance.

It is possible to improve your physical health by simply exercising and/or eating well. But, it won't tell you if you have succeeded. Goals must be clearly defined. In your professional life, unclear goals are just as likely to cause failure.

How to prevent it

CLEAR goals and Smart goals are two options for setting goals, but realistic, attainable goals are the most important. The goal of "losing weight" is not enough. Perhaps you want to lose fifteen pounds in a four-month period. You can accomplish this. It is even more important to clearly define your objectives in complex projects like yours

3. Lack of project visibility

A lack of visibility will lead to rapid failure regardless of how well-planned and planned your injection molding project is. Ideally, the project-management system should give visibility to all members of the team, not just the manager. Transparency, clear communication, task status transparency, and effective document management are examples of visibility.

What can be done to prevent it

When people know the status, they can adjust or help. Problem-solving becomes easier when people know the status. Managing documents is not complicated. A central digital storage space for all project files can simplify your job as a project manager.

4. Lack of communication

A injection molding project manager's communication should be transparent. Let your team know how you communicate.

What you can do to prevent it

Make sure everyone on your team knows what to expect and can use whatever technology you choose, regardless of whether it is text messaging, email, or a combination. Software that provides chat, group discussion, and other features can bridge these gaps.

Be clear about expectations and guidelines regarding what injection molding is needed.

5. Expansion of scope

Initially, everything seems so straightforward. The addition of a simple item or the expansion of a service by a customer can quickly lead to scope creep and an overlarge team. The problem arises when either of those scenarios occurs.

Parameters of the injection molding project were unclear from the beginning.

Teams are under pressure to perform tasks that weren't originally planned by their bosses or customers.

What you can do to prevent it

Project failure is often caused by scope creep. It can turn a great achievement into a disappointing failure if you don't allocate the time and resources needed to accomplish the additional tasks.

6. Expectations that are unrealistic

Many injection molding projects can be sabotaged because of stubborn optimism and unrealistic expectations.ity to see what team members can do and when they can do it is crucial for project managers. In order to communicate with the customer and your bosses, you must align the expectations with reality.

What you can do to prevent it

If you set realistic expectations and have the stakeholders on board, your team is more likely to succeed.

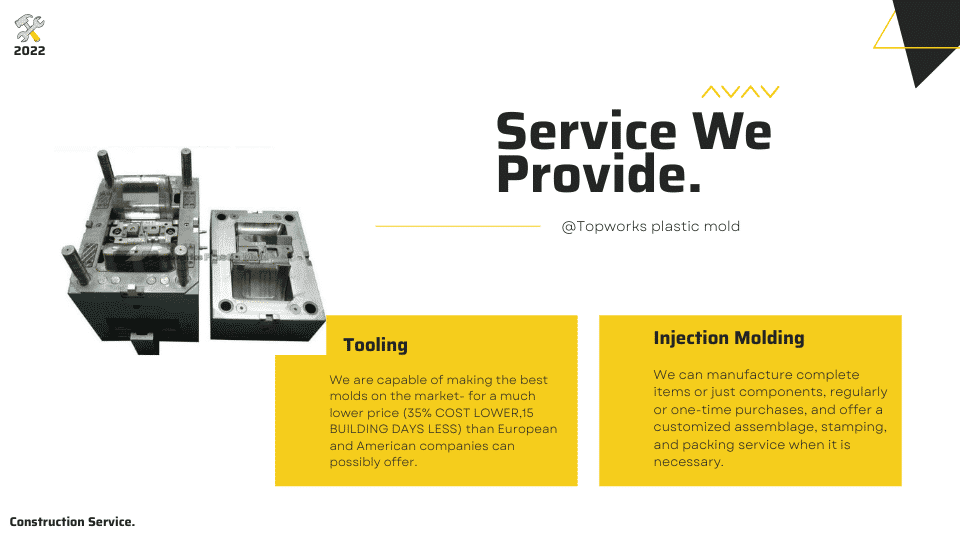

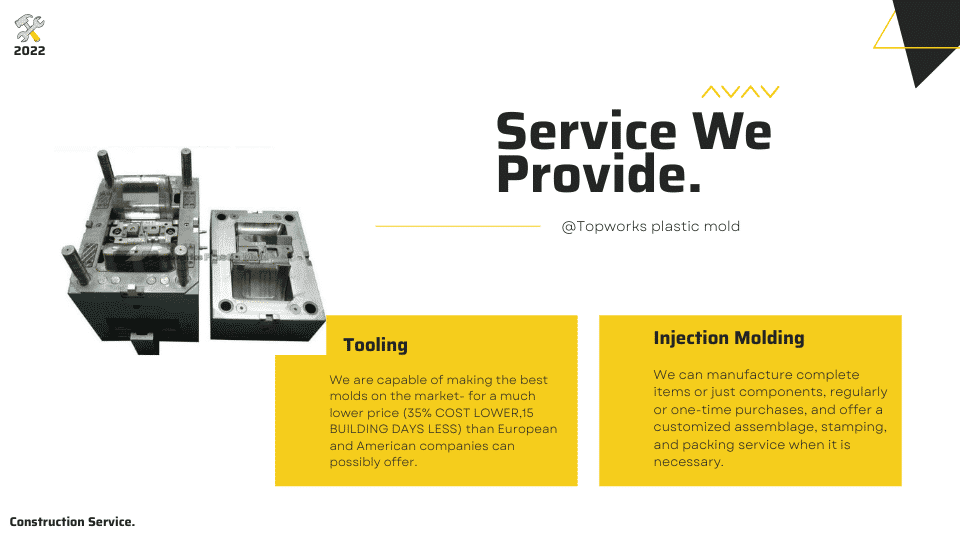

It can help you avoid project disasters through the Topworks Project

There are new methods available to avoid project disasters, despite the risks of disaster being known for centuries. You can prevent project failure using project management tools by keeping your goals in focus, assisting with resource planning, and providing visibility.

By using a great project management platform, it is possible to eliminate the questions regarding why projects fail, and instead focus on the execution of your projects.

Projects and other tasks can be managed with Kissflow Project. Everyone can access its digital workspace, and it is easy to use. As well as offering beautiful visual tools, Topworks Project also comes with built-in communication features to help you get the most out of your next project.

https://www.plasticmoulds.net/why-your-injection-molding-project-failed.html?feed_id=25&_unique_id=6299e5e7991f2

If the injection molding project doesn't deliver on time and within budget, it is considered a failed project. But, most of the time, the success or failure of a project is decided by its stakeholders. They judge the outcome and are satisfied with it.

A project can also be deemed a failure when it fails to meet the ROI target and/or the financial forecast.

There are many reasons. But the good news? You can conquer each obstacle to make your next project, and every one after that, successful. Learn some injection molding project management basics.

There are many factors that could cause a project to fail. One reason is that there are changes in organizational priorities. Also common is a change of project objectives, unclear risk definition and poor communication. Kissflow Project helps you to stay on top of your project and avoid failure.

If the injection molding project doesn't deliver on time and within budget, it is considered a failed project. But, most of the time, the success or failure of a project is decided by its stakeholders. They judge the outcome and are satisfied with it.

A project can also be deemed a failure when it fails to meet the ROI target and/or the financial forecast.

There are many reasons. But the good news? You can conquer each obstacle to make your next project, and every one after that, successful. Learn some injection molding project management basics.

There are many factors that could cause a project to fail. One reason is that there are changes in organizational priorities. Also common is a change of project objectives, unclear risk definition and poor communication. Kissflow Project helps you to stay on top of your project and avoid failure.

Comments

Post a Comment