4 Steps To Help Getting An Accurate Plastic Mold and Plastic Parts Offer From China

With the continuous improvement of the level of mold manufacturing and mold workers' skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories.

The continuous deepening of information exchanges between the two sides has greatly promoted the development of China's mold industry.

For those buyers who often purchase in China, it is simple to deal with China's mold and injection molding suppliers.

But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China's mold factories outside of thousands of miles.

Language and technical communication constitute two significant obstacles.

For many people who bought customized plastic parts in China for the first time, they were completely unfamiliar with this industry.

Also, this industry is technology-intensive, the quotation requires suppliers and buyers to have a good interaction.

The most important is how the buyers express their ideas to the suppliers.

It is precisely at this point that many buyers do not know how to handle it.

They often ask the supplier for a price from the very beginning.

In fact, the price given by the supplier at this stage is very inaccurate.

I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding.

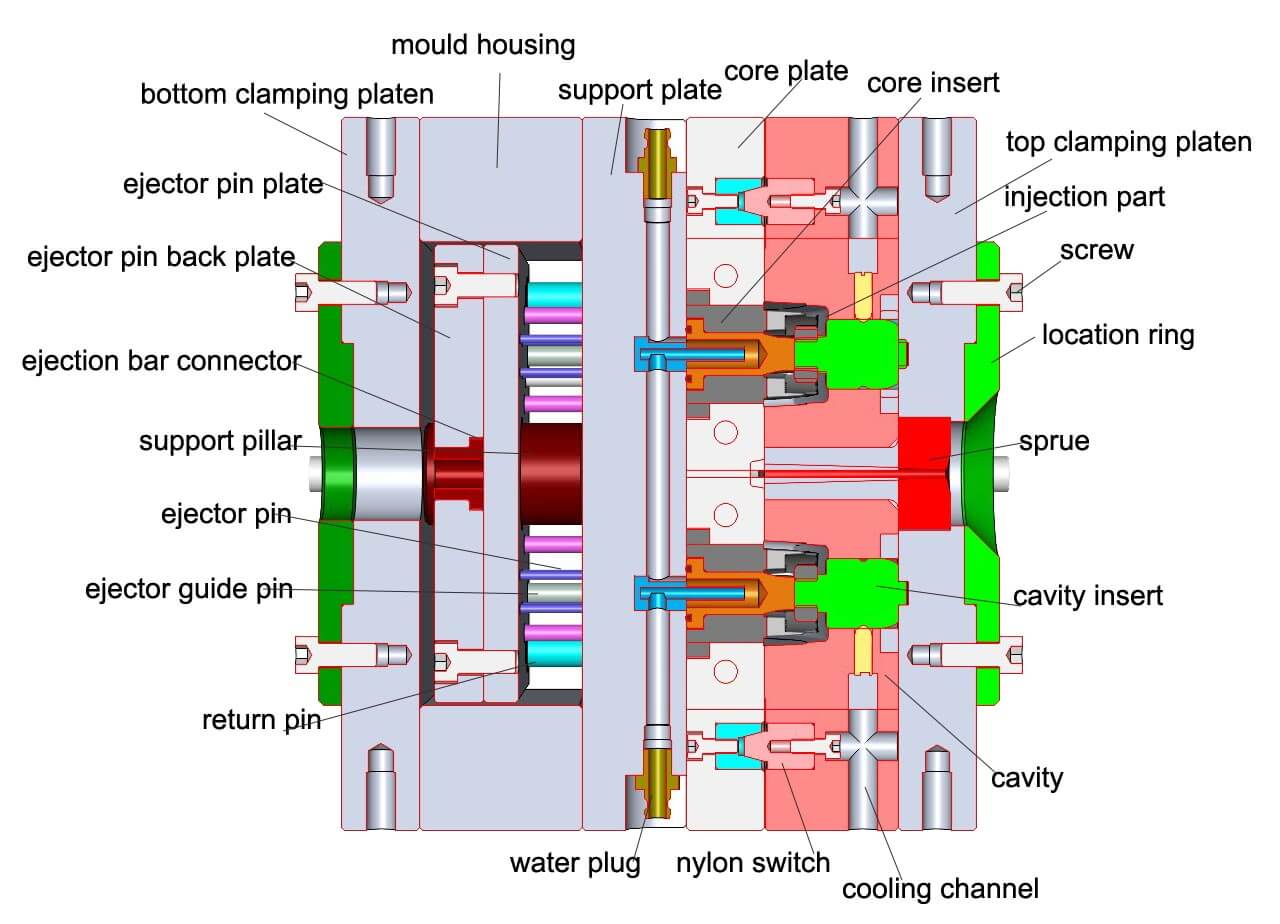

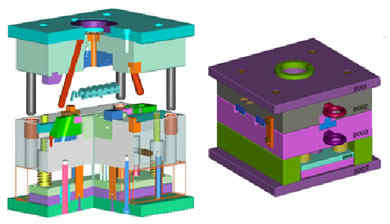

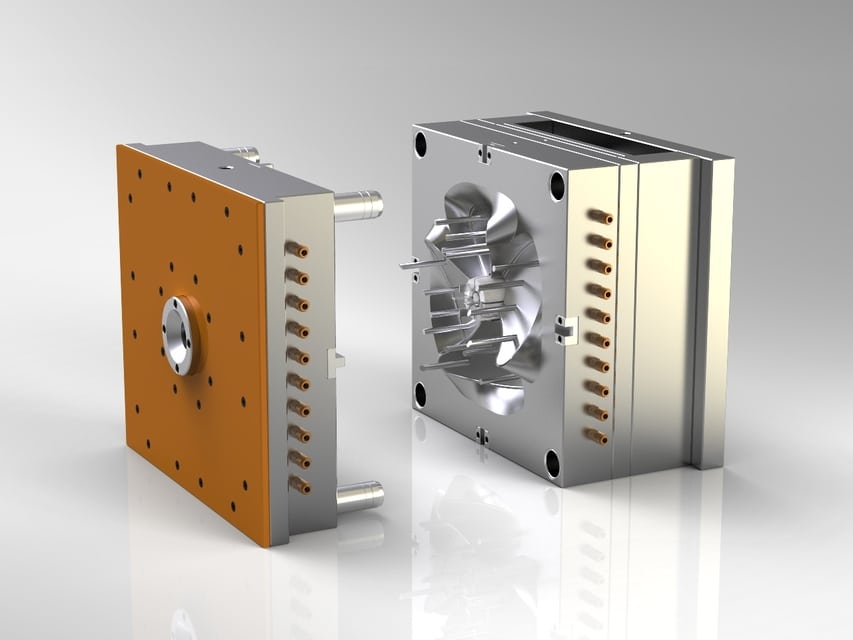

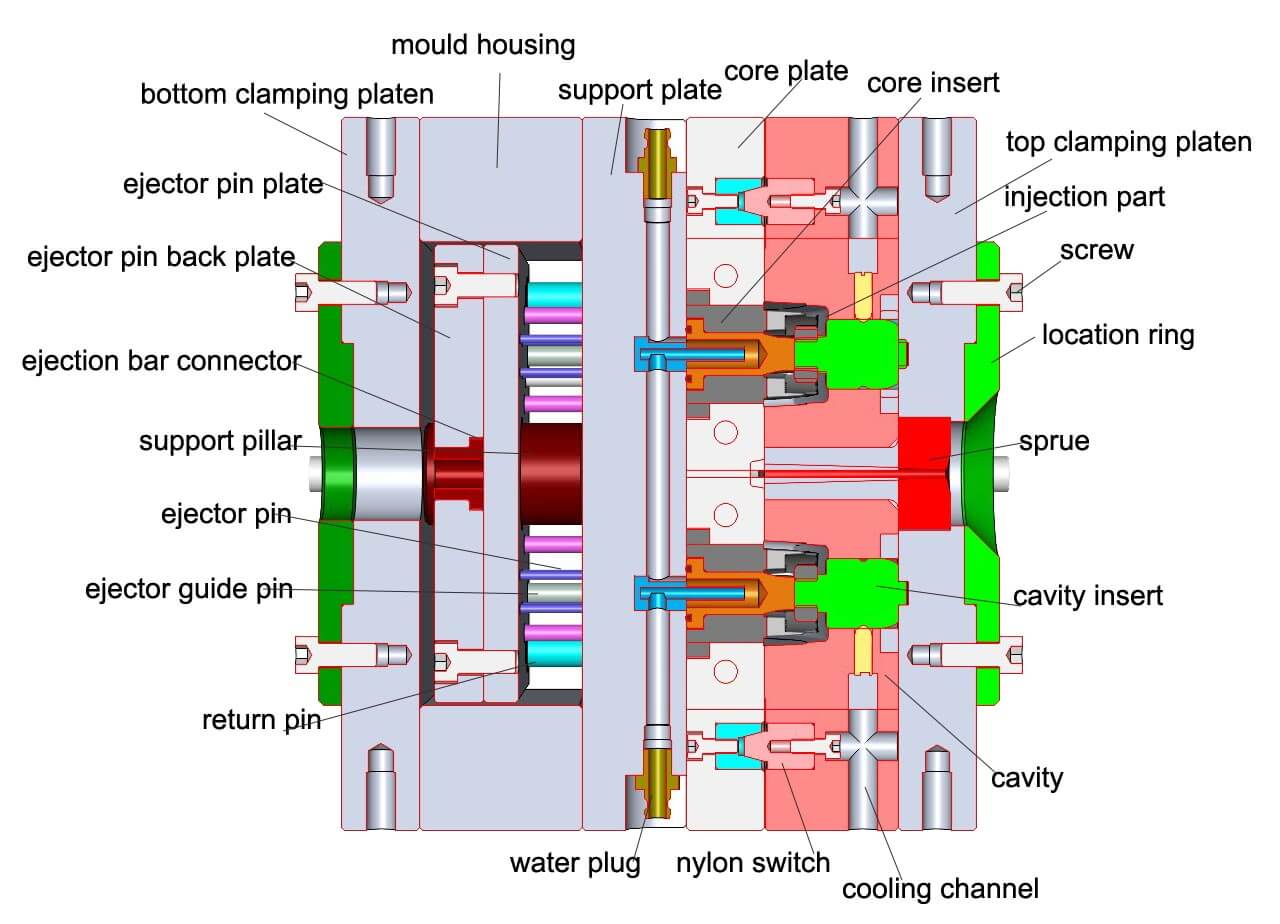

The manufacture of injection-molded parts is a very complicated process.

The first is the manufacture of molds, followed by the injection molding and second operation of injection-molded parts, which involves the transfer of a lot of information.

The top priority is how the buyer expresses his product requirements clearly to the supplier.

In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials.

Buyers just mentioned adjectives like "soft "and "hard" to describe the stuff he wants.

In fact, this is incorrect.

The correct way is to find an injection molding engineer or mold engineer around you to consult with them.

This early investment is necessary, and this investment will be paid-off in the future.

Of course, I would be happy to provide you with this service, but at this time, it is challenging for me to quote you also.

You should find a very experienced engineer and tell him, face to face, what you think, the requirements for the product, the quantity requirements, the assembly requirements, and so on.

He will give you good advice based on your actual situation.

During this period, he will tell you which plastic material to choose, how to design the product, how to assemble, and how to arrange the reasonable quantity.

After the above is completed, the 3D drawing design of the product can be performed.

You can tell the design engineer your requirements in great detail.

They will make the appropriate design according to your needs.

After the preliminary design is completed, you should do rapid prototyping at this stage to check whether your design intent has been achieved for new developments or changes to the old product.

Rapid prototyping allows inspection of the appearance, assembly, and strength of a designed product.

Modify the problematic design and make a new 3D printing.

Repeat this process until the final 3d printing meets the requirements.

This cost is relatively small, with short time, and it can avoid costly and time-consuming mold changes later.

In China, generally speaking, the cost of a small 3D printing is about 50 to 60 US dollars.

This step may save you thousands of dollars later.

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

[button size="large" align="left" full="true" link="https://plasticmoulds.net/contact-us" linkTarget="_blank" width="126" nofollow="true"]Get A Quotation[/button]

[divider_top]

Of course, if you just want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction.

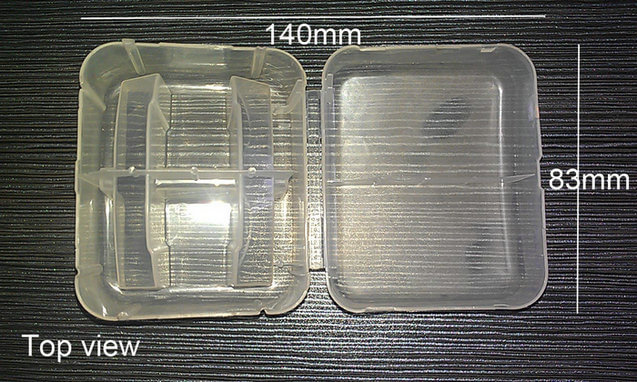

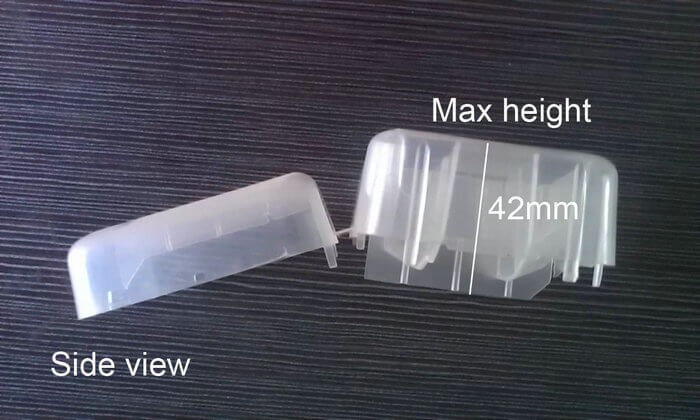

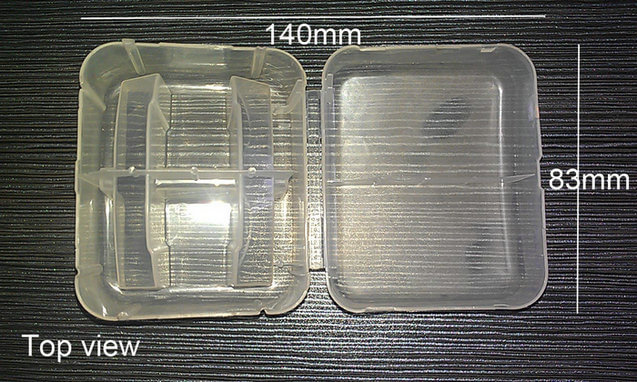

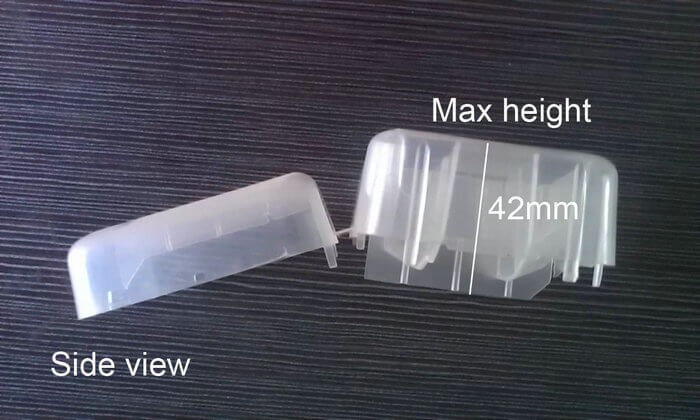

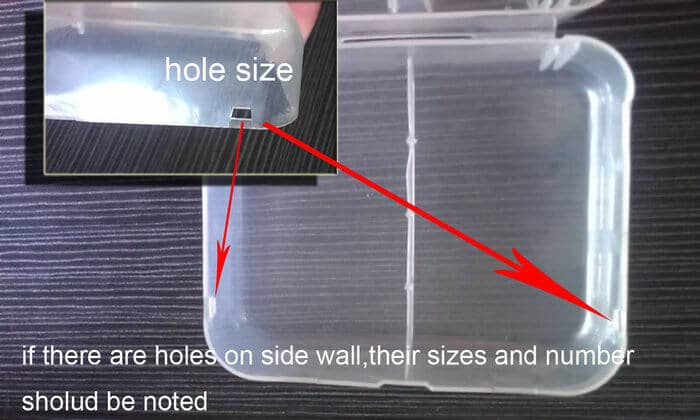

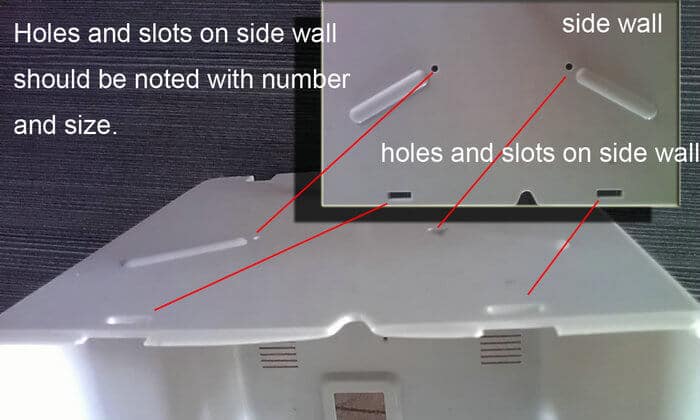

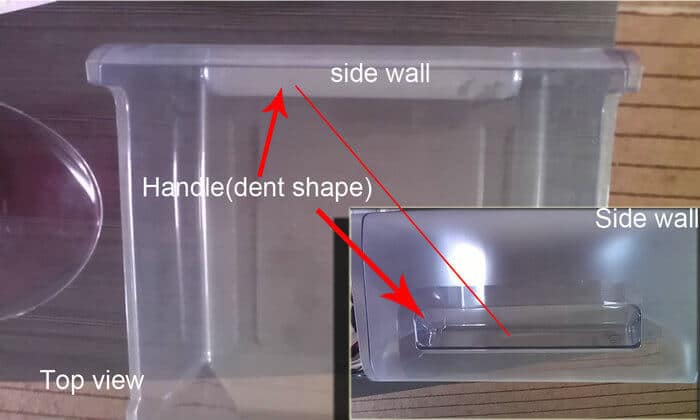

If you have only one sample and inconvenient to send it, you can take a picture of the sample.

According to the three-view standard, you show suppliers a sample photo.

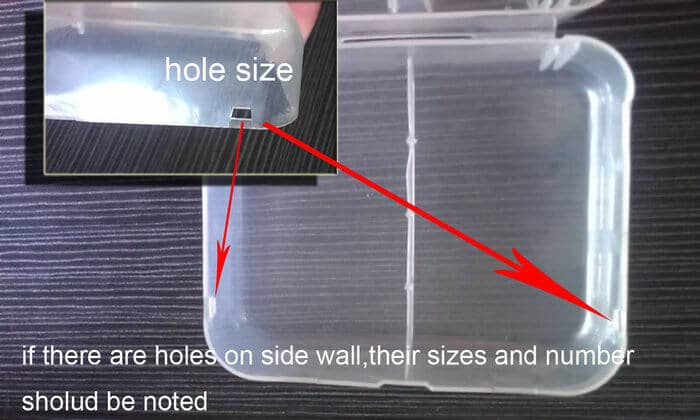

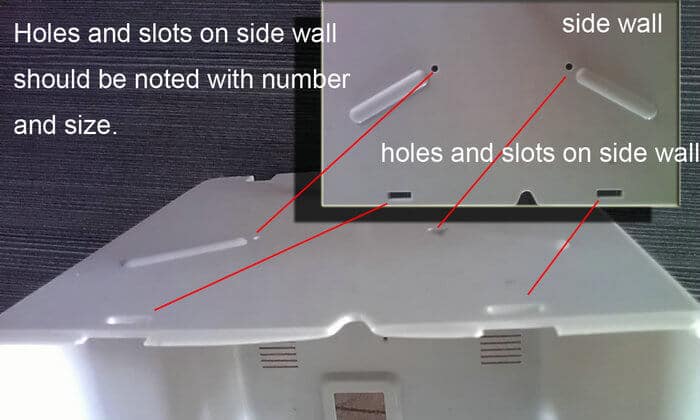

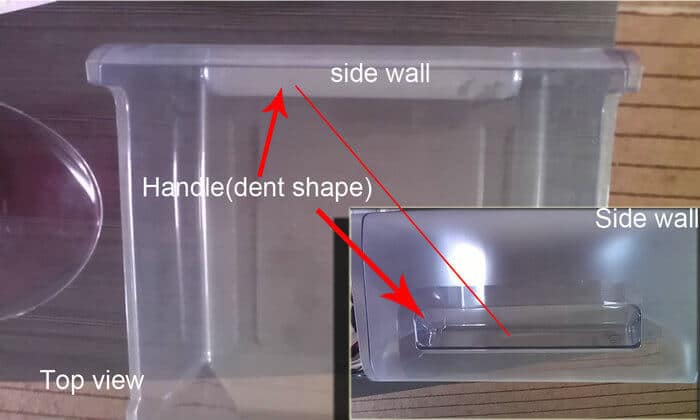

Mark the position and size of the undercut, dents, and holes in each direction on the picture.

In the photo, the size of the product is identified in detail, i.e. the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is.

#Case 1

[ngg_images source="galleries" container_ids="7" display_type="photocrati-nextgen_basic_thumbnails" override_thumbnail_settings="0" thumbnail_width="240" thumbnail_height="160" thumbnail_crop="1" images_per_page="20" number_of_columns="0" ajax_pagination="0" show_all_in_lightbox="0" use_imagebrowser_effect="0" show_slideshow_link="1" slideshow_link_text="[Show slideshow]" order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]# Case 2

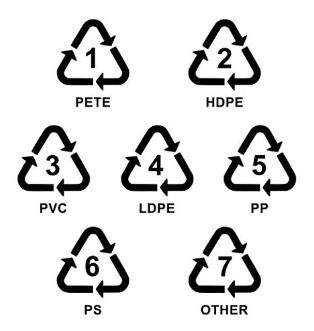

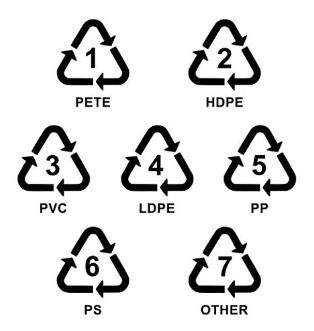

It is best if you can find the specifications of plastic materials on the sample, and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle.

In the end, you still have to send this sample to your final supplier to facilitate their design.

The number of purchases dramatically determines the price of the product and the plastic mold.

As long as the product is only 10,000, do not put forward a requirement of 500,000, because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements.

If the number of products is 10,000, the four-cavity mold can meet the requirements.

If it is 500,000, the mold will require 10, 12 cavities or higher.

The more the number of cavities is, the higher standards of the steel material and processing requirements will be.

This will lead to a significant increase in the material cost and processing cost of the mold.

The considerable quantity shares these costs.

If the quantity is small, then the cost sharing of each product will be high.

I have encountered a case where there is an ABS molded product.

The annual demand is 1500 sets.

It is internally threaded and needs to be unscrewing.

If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert.

The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small.

In general, dark-colored products need lower prices than light-colored products.

Because in some cases, the regrind material can be used, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier's raw material costs.

Frequently, the runner material and the new material have the same effects.

The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in.

If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is a good product.

As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one.

Molds with tight tolerances have very stringent requirements for processing and mold steel and even require unique injection molding process.

In general terms, the plastic we choose should be conventional plastics, not engineering plastics.

Nylon66 flare-retardent grade "v0" price is more than four times the conventional PP plastic.

The cost of the ordinary ABS is 1.5 times the price of PP.

If it is mass production, the cost difference is great.

Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold.

There are also higher requirements for mold maintenance.

The price of the steel s136 level is more than five times that of the steel p20 .

Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method.

By this way, the molder can clearly know the structure of the product and can also find out the structure of the previous mold.

Research on off-the-shelf samples can avoid many detours in molds building and injection molding products.

In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is.so that the accuracy of the quotation can be guaranteed to the greatest degree.

At the same time, it ensures the smooth progress of the project.

[divider_top]

You might consider it challenging to purchase an injection mold, because there are going to be a great deal of to and fro between purchaser and molder prior to when the last item is concluded on.

Nevertheless, the few suggestions here can help to conserve lots of time, and help to make the entire procedure that a bit simpler.

When you buy an injection mold, that age-old proverb is unquestionably correct - it gives you everything you pay money for. Any specific shaped parts that you develop are only just like the mold employed to manufacture them, which means you should make certain that plastic mold is flawlessly designed for your requirements prior to purchasing it.

The continuous deepening of information exchanges between the two sides has greatly promoted the development of China's mold industry.

For those buyers who often purchase in China, it is simple to deal with China's mold and injection molding suppliers.

But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China's mold factories outside of thousands of miles.

Language and technical communication constitute two significant obstacles.

For many people who bought customized plastic parts in China for the first time, they were completely unfamiliar with this industry.

Also, this industry is technology-intensive, the quotation requires suppliers and buyers to have a good interaction.

The most important is how the buyers express their ideas to the suppliers.

It is precisely at this point that many buyers do not know how to handle it.

They often ask the supplier for a price from the very beginning.

In fact, the price given by the supplier at this stage is very inaccurate.

I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding.

The manufacture of injection-molded parts is a very complicated process.

The first is the manufacture of molds, followed by the injection molding and second operation of injection-molded parts, which involves the transfer of a lot of information.

The top priority is how the buyer expresses his product requirements clearly to the supplier.

In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials.

Buyers just mentioned adjectives like "soft "and "hard" to describe the stuff he wants.

In fact, this is incorrect.

4 Steps for plastic mold quotation:

#Consult with experts

The correct way is to find an injection molding engineer or mold engineer around you to consult with them.

This early investment is necessary, and this investment will be paid-off in the future.

Of course, I would be happy to provide you with this service, but at this time, it is challenging for me to quote you also.

You should find a very experienced engineer and tell him, face to face, what you think, the requirements for the product, the quantity requirements, the assembly requirements, and so on.

He will give you good advice based on your actual situation.

During this period, he will tell you which plastic material to choose, how to design the product, how to assemble, and how to arrange the reasonable quantity.

#CAD design

After the above is completed, the 3D drawing design of the product can be performed.

You can tell the design engineer your requirements in great detail.

They will make the appropriate design according to your needs.

#Rapid prototyping

After the preliminary design is completed, you should do rapid prototyping at this stage to check whether your design intent has been achieved for new developments or changes to the old product.

Rapid prototyping allows inspection of the appearance, assembly, and strength of a designed product.

Modify the problematic design and make a new 3D printing.

Repeat this process until the final 3d printing meets the requirements.

This cost is relatively small, with short time, and it can avoid costly and time-consuming mold changes later.

In China, generally speaking, the cost of a small 3D printing is about 50 to 60 US dollars.

This step may save you thousands of dollars later.

#Quotation

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

[button size="large" align="left" full="true" link="https://plasticmoulds.net/contact-us" linkTarget="_blank" width="126" nofollow="true"]Get A Quotation[/button]

[divider_top]

How to copy existing products

Of course, if you just want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction.

If you have only one sample and inconvenient to send it, you can take a picture of the sample.

According to the three-view standard, you show suppliers a sample photo.

Mark the position and size of the undercut, dents, and holes in each direction on the picture.

In the photo, the size of the product is identified in detail, i.e. the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is.

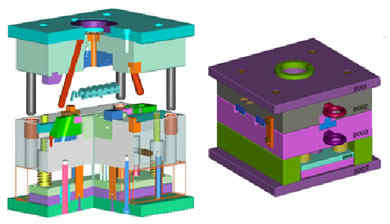

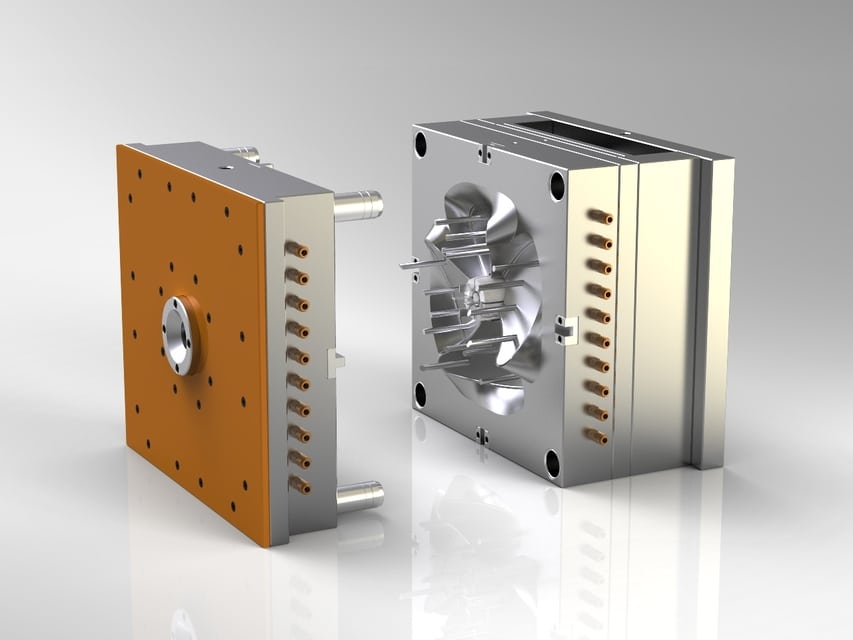

#Case 1

[ngg_images source="galleries" container_ids="7" display_type="photocrati-nextgen_basic_thumbnails" override_thumbnail_settings="0" thumbnail_width="240" thumbnail_height="160" thumbnail_crop="1" images_per_page="20" number_of_columns="0" ajax_pagination="0" show_all_in_lightbox="0" use_imagebrowser_effect="0" show_slideshow_link="1" slideshow_link_text="[Show slideshow]" order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]# Case 2

It is best if you can find the specifications of plastic materials on the sample, and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle.

In the end, you still have to send this sample to your final supplier to facilitate their design.

4 main points related to plastic mold and injection part price

Quantity

The number of purchases dramatically determines the price of the product and the plastic mold.

As long as the product is only 10,000, do not put forward a requirement of 500,000, because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements.

If the number of products is 10,000, the four-cavity mold can meet the requirements.

If it is 500,000, the mold will require 10, 12 cavities or higher.

The more the number of cavities is, the higher standards of the steel material and processing requirements will be.

This will lead to a significant increase in the material cost and processing cost of the mold.

The considerable quantity shares these costs.

If the quantity is small, then the cost sharing of each product will be high.

A case

I have encountered a case where there is an ABS molded product.

The annual demand is 1500 sets.

It is internally threaded and needs to be unscrewing.

If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert.

The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small.

Color

In general, dark-colored products need lower prices than light-colored products.

Because in some cases, the regrind material can be used, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier's raw material costs.

Frequently, the runner material and the new material have the same effects.

The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in.

If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is a good product.

Tolerance

As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one.

Molds with tight tolerances have very stringent requirements for processing and mold steel and even require unique injection molding process.

Plastic materials

In general terms, the plastic we choose should be conventional plastics, not engineering plastics.

Nylon66 flare-retardent grade "v0" price is more than four times the conventional PP plastic.

The cost of the ordinary ABS is 1.5 times the price of PP.

If it is mass production, the cost difference is great.

Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold.

There are also higher requirements for mold maintenance.

The price of the steel s136 level is more than five times that of the steel p20 .

Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method.

By this way, the molder can clearly know the structure of the product and can also find out the structure of the previous mold.

Research on off-the-shelf samples can avoid many detours in molds building and injection molding products.

In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is.so that the accuracy of the quotation can be guaranteed to the greatest degree.

At the same time, it ensures the smooth progress of the project.

[divider_top]

How To Buy The Plastic Mold Easier

You might consider it challenging to purchase an injection mold, because there are going to be a great deal of to and fro between purchaser and molder prior to when the last item is concluded on.

Nevertheless, the few suggestions here can help to conserve lots of time, and help to make the entire procedure that a bit simpler.

- Produce an RFQ that explores a wide range of specifics.As experienced as moldmakers are usually, they won't manage to go through your head when considering what you're interested in. Consist of as numerous details as possible during this period, like the variety of cavities, the material, the required life expectancy of your mold, and any specific warranties you may possibly require. Should you aren't very confident on such subjects, then inform your mold maker, and they will be ready to show you how to choose what's proper for your requirements. The more precise you come up with your RFQ, the more correct an offer you will get for your efforts.

- Be honest about the reason why you need an offer. Should you just require a overall quote to spread to a different unit, then let the mold maker fully understand- they are going to then get back to you rapidly. Developing a precise quotation can acquire much time, and it's not considerable to misuse the mold maker's time if you don't require too much information, or when you won't actually get from them.

- Don't "STEAL" a mold maker's property. The information and recommendations provided by your mold maker keep on being their own intellectual property- you can't merely bring these tricks to other people to get it done . Should you come up with another moldmaker, in that case consider their recommendations agreeable - not just is employing someone else's suggestions,it is not fine.However it may also obfuscate the minds of your chosen mold maker, who won't comprehend precisely why those recommendations were created initially.

- Try to develop a relationship with your mold maker. Simply by doing business tightly with your moldmaker when considering costs, schedules, and component amount anticipations, you?ˉll have the know-how to behave as a crew to attain better outcomes over time.

- Have an Open Door Policy with your mold maker over the all course. A lot of mold makers will love to present routine development information and maintain you up-to-date around the most recent advancements with your construct. It's essential to fully understand things are all moving to routine, so when you require any specific details, make it a point to inquire about that allows you to put the mind relaxed.

- You should definitely pay on time. Most mold makers get the job done to a constrained resources and will need costs to be settled before they can move forward for your project. Should you postpone paying, then you certainly won't receive a mold by the due date - it's so simple as that. Various mold makers will present diverse settlement strategies, so meet with these people to come up with a strategy that is effective for the two of you.

- A modification of your component structure will almost certainly indicate altering the injection mold as well. Should you result to changing your component structure as the injection mold is being developed, you won't obtain the mold at a cost offered, or to the primary schedule. Any kind of modifications indicates the mold must be modified as a result, which increases both the expense and the duration of the mold construct.

- Recognize ahead of time when mold will be ready. There are various explanations on a finalization time - some may vary from once the final settlement is completed, to the time you be given a trial component, to delivery of the finalized item. Typically, an injection mold is recognized as finished when it is in a position to create the component it is for the purpose of. The vast majority of mold makers will be ready to come up with tiny modifications to ensure a component as outlined by design. If these measurements alter later hanging around, in that case the injection mold should be regarded as finished - the actual modifications should be given money for via an ECO.

- If a product is unreasonably low price, you will find typically an explanation for that. While you will see mold makers on the market who present you with a cheaper-than-average price for a top notch product or service, we will see lots of others who present reductions as they spend less money on their own. Over time, it's preferable to pay big money for a high-quality product or service, as opposed to obtaining headache by using a mold that doesn't meet up with your requirements.

When you buy an injection mold, that age-old proverb is unquestionably correct - it gives you everything you pay money for. Any specific shaped parts that you develop are only just like the mold employed to manufacture them, which means you should make certain that plastic mold is flawlessly designed for your requirements prior to purchasing it.

[…] you contact the plastic mold supplier, you should make some preparations(AUTOCAD drawing or […]

ReplyDeletegeneric viagra best price http://canadian-healthy.com/ - viagra coupons for pharmacy

ReplyDeleteviagra 100mg

generic viagra from us pharmacy viagra viagra 100mg

buying viagra http://pharmexpresstore.com/# - non prescription viagra

ReplyDeleteorder viagra india

coupon codes for viagra order generic viagra buy viagra los angeles