Now Is The Time For You To Know The Truth About Plastic Design

Plastic materials move after getting heated up to the suitable temp (which can vary with every single materials). This kind of capability might be tested by evaluation, working with a melt index device per ASTM Test #D-1238.

This capability to flow likewise confirms what lengths a plastic material could be shot with a certain wall thickness of a item.

Should the substance is an easy-flow content (having a high melt index), it could move significantly for more distance when compared to a hard-flow material.

Furthermore, the easy-flow substance may flow into the considerably thinner wall portion when compared to a substance that isn't easy-flow.

Low-flow, more rigid materials are likely to cool off and harden prior to they could flow as long as the easy-flow (not so rigid) materials.

It could be observed, subsequently, that some substances can occupy thin walls better as opposed to others, subject to their melt index merit and rigidity.

Since the wall thickness suggestions are signals, it is usually advisable to develop a plastic component as thin as possible, but needs to be fulfilled effortlessly.

The majority of developers are inclined to produce plastic components a lot thicker as compared to what they need. This brings about substantial and high priced cycle times and issues in dealing with sizes.

In the event that thick parts are important for durability reasons, it is advisable to employ a thin wall and incorporate stiffing ribs.

Molten plastic material passes from the course of minimum resistance.

If every one of the walls of a particular item are even, the plastic moves with smaller efforts and minimal reduced pressure while it goes over the given flow course.

The majority of the molecules in the substance results in being alike in dimensions, and occupy similar quantities of size, along with similar quantities of area together.

Knitted lines (or weld lines as it is also known as) would be the consequence of a move front of melted materials in contact with a blockage within the mold, splitting into 2 fronts to circulate around the blockage, and interacting with on the opposite side to try and weld together again .

The head of these fronts are going to have cooled off considerably while moving surrounding the blockage and aren't in a position to welding together to a full degree.

Therefore, they will develop what is known as a knitted line, that is considered to be the first step of a break.

A sharp corner within a component is surely a reason for problems. Sharp corners are tips of stress focus, acquiring stress in 3 fundamental varieties: tensile, pressure, and shear.

Sink dings are produced when 2 regions of a component cool down and harden diversely from one another. That is the result of a thinner segment being solid ahead of a thick portion.

A created component seems deformed, turned, or bowed, could be the outcomes of stresses established over the creating procedure, or soon after the time the component is shot .

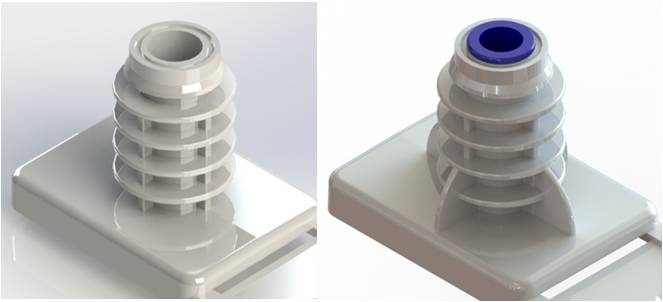

One of the dubious facets of injection-molding item style is the importance of draft. In its most basic words, draft is regarded as a a taper put on side walls. It can also be regarded when it comes to an ice cube holder.

All the ice cube holder cells possesses tapered walls permitting the ice to remove effortlessly from the holder. The item requires tapered walls to let the component to remove effortlessly out of the mold.

The level of taper utilized is termed the "draft angle"

Ejector pins genuinely develop portion of a face within the molded component. If the pins are designed short they will likely result in a "cushion" of unwanted plastic material to produce on this face.

Should the pins are very prolonged, the plastic material will move surrounding them and result in a recession on the component.

When surface gates are employed, as soon as the created component is trimmed over the entrance, a recession or outcropping will probably be left behind, subject to the way the gate was developed originally.

If hot runners are employed, there will probably continue to be a sign, however it will be not as noticeable.

Should be officially claimed that the item sketching requires priority over other strategies ,it was showing an item developer's desires to the producing deamans of the marketplace.

Consequently, it has to be perfectly planned and readable for all requiring to watch it. Conventional types should be utilized, and measurements needs to be looked over to guarantee you don't see any instances of double-dimensioning, or measurements overlooked. Examples of these are widespread circumstances causing a lots of misunderstandings.

click for more design details.

Comments

Post a Comment