how to solve injection molding 'full-service' issues

The customer deals with one vendor when dealing with a "full-service" vendor. Vendors, usually molders, are responsible for providing the finished injection molded product to customers. Upon receiving the customer's request, the molder arranges all the necessary steps to fulfill it. Molders who have all of those capabilities in-house do not have to worry about customer responsibility in that case. In any case, if a molder needs to go outside for certain processes or activities, he or she still bears full responsibility for the finished product's success. That's why it's called "full service." It's designed to simplify the process of obtaining the final product by eliminating the hassles associated with it sometimes. In full-service vendors, all problems are handled and details of responsibility are worked out without customer involvement.

It's quite possible that a client doesn't require a full-service provider. It could be for instance, if the customer is able to use an internal molding facility but doesn't have an in-house mold design or build operation. In this case, the customer could develop a mold and have it constructed outside and brought into the house to carry out the molding process. This presents an completely new set of issues in the area of accepting the responsibility. The moldmaker relies upon the designer of molds for the design from the client.

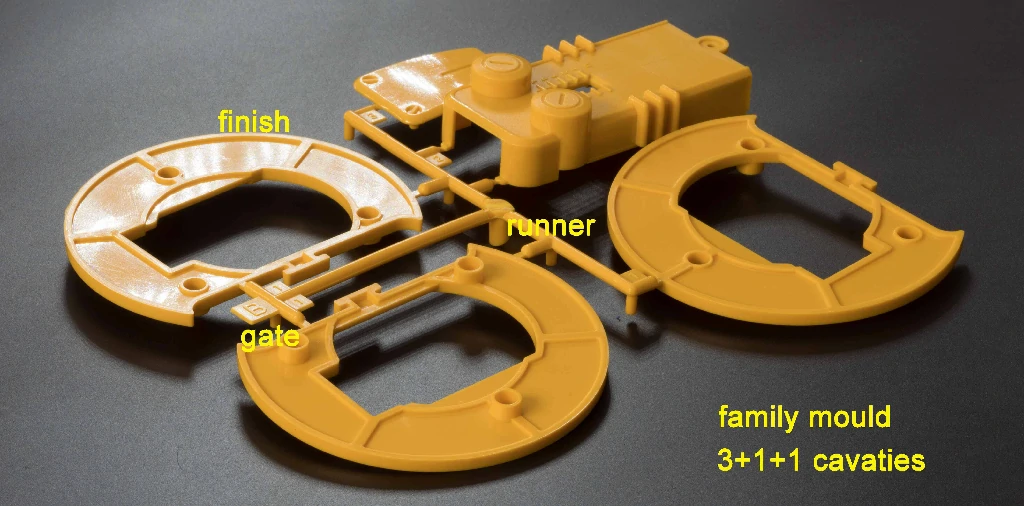

This can include things like the determination of shrink factor (in every direction and in all locations) as well as the proper choice of the mold steel type and authorized gate and ejector pin places, as well as a variety of other things. The moldmaker assumes the designer of the mold has gotten permission from the customer to do the above items, should they be required. However the mold designer presumes that the client has chosen a mold maker who has a good understanding of the needs of the customer and can construct molds from the information provided to the mold maker.

There is the potential for only a small amount of communication between the two suppliers as they both make sensible assumptions about each other. When the finalized mold is delivered at the customer's location to be tested the parts, they may not be in compliance with the requirements of the customer. A quick battle ensues where the customer blames the mold maker and the moldmaker taking blame for on the mold maker. The mold designer blames the mold maker and the customer. It is possible that to fix the issue the only option the customer has is to shell out more money and spend longer time to make "someone" fix the mistake. It could require the effort and time that the venture will fail due to missing the opportunity to fix it.

To resolve the issue of responsibility in this kind of situation , it is advisable for the client to assume as much of the responsibility throughout the project. Although this might seem counter-intuitive initially, the outcome is that the client receives what they need and the overall price will typically be significantly less (by 20 percent and more). The reason is that the vendor can offer lower rates because they don't need to consider bringing in the cost of rework into their estimates. The customer is obligated, beforehand, to pay for there is a need for rework. However the person who is in charge must be able to supply all the necessary information to vendors, including shrinkage rates as well as mold steel types and other information that were previously mentioned.

If this isn't feasible the client should work as closely as is possible with all vendors involved, by holding regular group meetings, and making frequent inspections to make sure everyone is communicating with each other and operating in a similar degree of cooperation. Even so, mistakes will be made. The customer and the vendor dors must agree prior to the project's start on who is accountable for which part in the process. This will reduce the stress and conflict that are likely to arise bewhen the project comes to its conclusion.

It is generally advantageous-both in terms of time and cost-to choose a full service provider over a set of service providers who are dedicated. However, several aspects must be taken into consideration prior to making this choice. The financial aspect will likely be the dominant factor but the aspect of accountability should not be overlooked. If a vendor isn't willing to assume the responsibility that is typically considered to be their accountability, it must be considered as an indication that could lead to the search for a vendor that will.

https://www.plasticmoulds.net/how-to-solve-injection-molding-full-service-issues.html?feed_id=1154&_unique_id=63b51e72814be

Comments

Post a Comment