China injection molding,plastic injection molding company-Topworks

Why China injection molding-Topworks?

Injection molding overseas is not cost-effective for most companies. The high shipping costs and delivery delays by overseas customs would make it inefficient, so make it locally? You have likely heard negatively about the quality of plastic injection molding companies in China. However, the plastic mold outsourcing industry within China has grown consistently. Many companies worldwide continue to purchase China plastic injection molding or China injection molding services; some are placing large orders, and some even set up their own sourcing office in China. People prefer advanced mold injection technology and durable injection parts. The Chinese mold supplier is a reliable business partner in the injection mold industry. As a Chinese custom-made plastic mold manufacturer, Topworks takes pride in offering our customers the best quality in plastic molds made using advanced tech. With over a decade of experience, Topworks take on each project with high levels of expertise and dedication, and we provide you with a skilled, knowledgeable, and committed staff dedicated to your plastic injection molding needs. Topworks can manufacture a complete item throughout our manufacturing process, or just parts of a system, regularly or on an ad-hoc basis, and offer custom assembling, stamping, and packaging service when needed and necessary. All Topworks employees are skilled in their particular design, mold building, and plastic molding, making it possible for us to design, manufacture, and deliver your plastic molding requirements. Our services include prototyping to production to meet each project's requirements. [framed_box bgColor="#9BCD9B"][slogan size="small" buttonText="Click for Quotation" buttonLink="https://plasticmoulds.net/contact-us" buttonLinkTarget="_blank" buttonColor="white"]See what we can do for you-30% lower,10 days less[/slogan][/framed_box]https://res.cloudinary.com/dl8a9jvpa/video/upload/v1478231506/MOULD_TEST_1_szswsp.mp4

China injection molding pros:

-

Price

-

Quality

-

Flexible work

-

Fast Delivery

-

Services

How to choose China injection molding?

The process of selecting reliable plastic injection molding companies in China can be confusing, as there are so many injection molding manufacturers in China, and they are all competing to win clientele. Different China injection molding makers provide various China mold services. What is the best way to choose a reliable, efficient injection molding maker in China? Will those China mold companies deliver as promised? How about the delivery time, quality, and intellectual property rights? You can find answers to these questions through the following items:- With the quotation sheet, you should verify the specifications of the steel insert used for the cavity and the core, the mold life, the number of cavities, the gate, the surface finish, the lead time for T1, the price, the delivery, and the payment.

- If you are interested in getting a China plastic injection molding service, you might want to ask the mold manufacturers for the DFM report before placing an order. This report will give you more information about those China plastic injection mold manufacturers. General information concerning mold properties, such as mold steel, mold shrinkage, feed system, and gate. And if a China plastic injection molding service fits your specifications, you can see how to optimize your part design.

- Review the quality system of the mold maker.

- Request references from past customers.

- Once the DFM and PO are confirmed, injection molders in China will start the design of the mold. You may ask the mold makers to send you the MoldFlow analysis based on the mold design to check the flowability, warpages, etc.

- After confirming the mold design, contact the China injection mold manufacturer to send you the tooling plan every week. You can also request the steel quality and hardness certificate from the mold manufacturer to check the steel quality and hardness.

- After the mold test, you will need to obtain the mold test video, the injection molding trial report, and the sample inspection report from the China mold maker.

- Please ask the China plastic injection mold supplier to send you the electrode and spare parts drawings and every other technical document before mold delivery.

Where to find plastic injection molding companies in China?

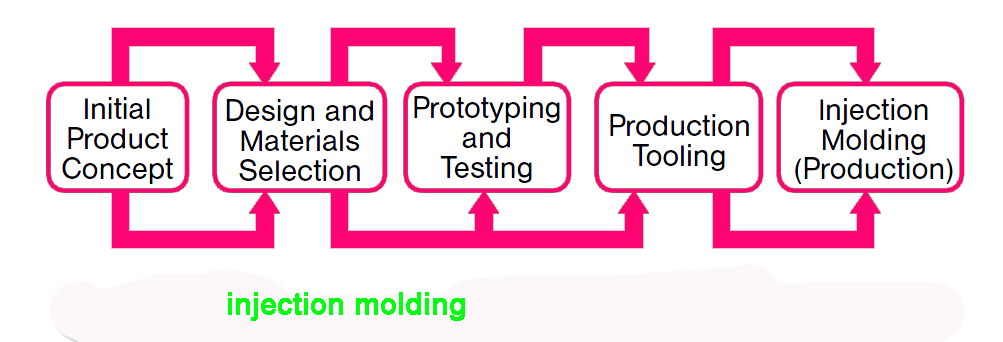

[caption id="attachment_5013" align="aligncenter" width="1003"] China injection molding cycle[/caption]

It is relatively simple to locate a manufacturer of injection molds in China.

You can search using the terms below: China plastic injection mold, China injection mold manufacturers, Chinese injection molding, Chinese mold manufacturers, etc.

China mold makers can be found on various social networking sites, such as Linkedin, Facebook, and Twitter.

The B2B websites Alibaba, Made-IN-China, Global sources, and others allow you to find China injection mold suppliers and manufacturers. Check out the Trade Shows like Canton Fair or Aisamold for injection mold service China.

In fact, you can find at least twenty of these organizations in the specialized industrial parts of Dongguan city. China at large should be considered as many distinct parts rather than a single large one.

Some areas are known for supplying the most China plastic injection molds. Currently, there is an extensive number of China mold suppliers. If you want to buy China plastic injection mold, you should seek a supplier located in one of these regions.

China has become the largest plastic consumer in recent years, while at the same time, China is home to the largest injection mold manufacturer with superior China injection mold service.

China Plastics manufacturers produce a large number of China Plastic Injection Molds, thereby creating a large market for acquiring these molds. As China mold factories grow increasingly sophisticated, so China mold suppliers also develop.

At present, the injection mold industry of China has its own distinct characteristics, dominated by the plastic molds produced in Zhejiang, Jiangsu, and Guangdong, which account for 70% of the national total output value, giving them a very competitive advantage.

China injection molding cycle[/caption]

It is relatively simple to locate a manufacturer of injection molds in China.

You can search using the terms below: China plastic injection mold, China injection mold manufacturers, Chinese injection molding, Chinese mold manufacturers, etc.

China mold makers can be found on various social networking sites, such as Linkedin, Facebook, and Twitter.

The B2B websites Alibaba, Made-IN-China, Global sources, and others allow you to find China injection mold suppliers and manufacturers. Check out the Trade Shows like Canton Fair or Aisamold for injection mold service China.

In fact, you can find at least twenty of these organizations in the specialized industrial parts of Dongguan city. China at large should be considered as many distinct parts rather than a single large one.

Some areas are known for supplying the most China plastic injection molds. Currently, there is an extensive number of China mold suppliers. If you want to buy China plastic injection mold, you should seek a supplier located in one of these regions.

China has become the largest plastic consumer in recent years, while at the same time, China is home to the largest injection mold manufacturer with superior China injection mold service.

China Plastics manufacturers produce a large number of China Plastic Injection Molds, thereby creating a large market for acquiring these molds. As China mold factories grow increasingly sophisticated, so China mold suppliers also develop.

At present, the injection mold industry of China has its own distinct characteristics, dominated by the plastic molds produced in Zhejiang, Jiangsu, and Guangdong, which account for 70% of the national total output value, giving them a very competitive advantage.

Comments

Post a Comment