What is Side Cores of Injection Mold

Side Cores

What are the best methods for releasing severe threads or cuts? Do side cores, splits, or other methods work?

In addition to the added complexity of the mold structure, adding any of these features will significantly increase the cost of the mold (and the cost of the product), not to mention the additional space each mold component takes up, compared to a simple mold design without side cores.

If the mold had the same number of cavities, it may be necessary to make it much larger and thereby larger the machine to accommodate this extra mold area, despite the clamping forces needed being lower than with a mold without side cores or splits.

If the mold has such features, such as side cores and splits, the cycle time will be longer and the productivity will be lower.

-

Should the product be redesigned to avoid the use of side cores?

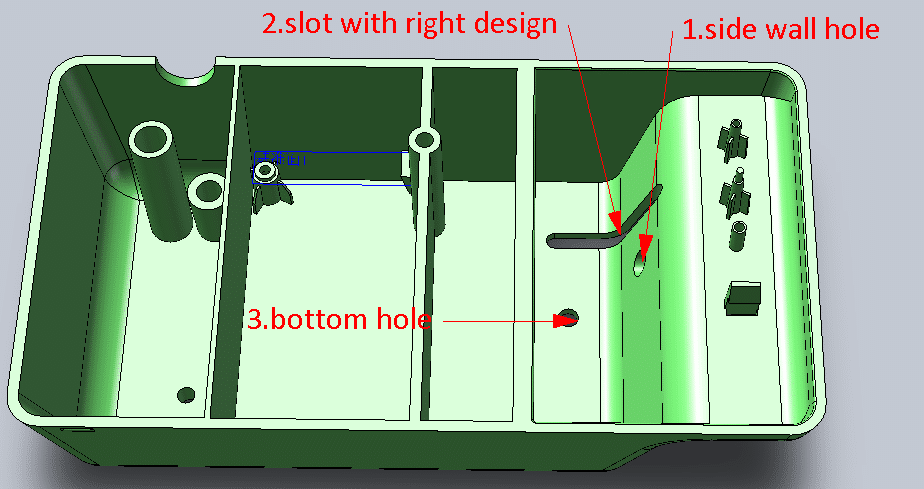

It may be possible to redesign round holes or openings of "odd shape" that arise from using split cavities or side cores without compromising the design of the product, the openings can be created in the side walls (or even in the ribs) with a design that blends the core and cavity together on a "shutoff". Special inserts may need to be inserted in the cavity or in the core, which may require altering the sidewall's shape (or draft angle), or even a hole in the bottom.

The end use of the product could be acceptable in many cases, and the mold could be simpler and therefore less expensive . In many cases, a little redesign can result in significant savings on mold and product costs by simply giving more consideration to the product design while planning and designing a mold.

-

Alternate Parting Lines

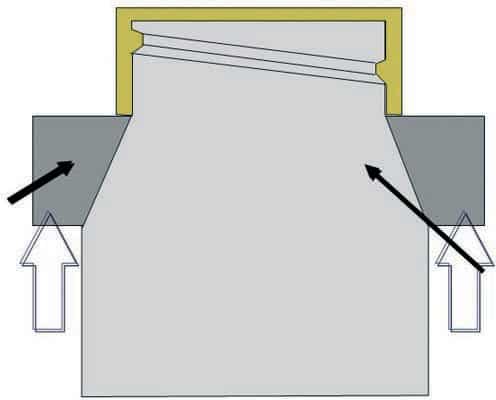

A parting line placed in the obvious location may require a side core whereas the same product can often be molded with an up-and-down mold by slanting the P/L. This principle applies to any similar case, such as a simple louver. "Slanted" P/L molds cost more than ordinary P/L molds, but are far less expensive than side core molds.

-

Study thread and undercut shapes

Often, a design specifies threads or undercuts, on the inside of the product . Is the specified shape of thread or undercut designed with molding in mind? Many such threads or undercuts could be molded without un- screwing, or the need for collapsible cores, by changing the shape of the undercut so that the product can be stripped off the core, i.e., the undercuts can easily slip out of the grooves that created them when pushed by ejectors or a stripper.

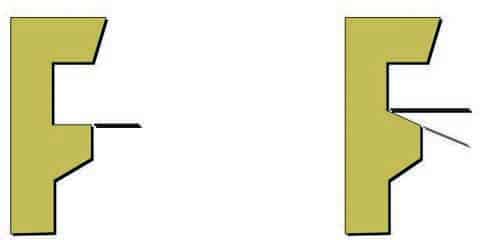

The left illustrates the difficulty of unscrewing a mold. Ejecting the cap from the cap mold requires rotating the core out. As a result, cooling the core becomes more difficult and cycle times increase by 30%. An unscrewing mold is more complex than a force ejection (stripped) mold.

The left illustrates the difficulty of unscrewing a mold. Ejecting the cap from the cap mold requires rotating the core out. As a result, cooling the core becomes more difficult and cycle times increase by 30%. An unscrewing mold is more complex than a force ejection (stripped) mold. A more simple mold is illustrated in the left by a thread (and cap) that can be stripped. A very efficient cooling method is available here. Typical (28 mm) HDPE bottle caps with a weight of less than 3 g, molded in a 24-cavity machine powering a 90 t (1,000 kN) machine, cycle in 4.0 seconds, producing 21,600 caps during an hour.

A more simple mold is illustrated in the left by a thread (and cap) that can be stripped. A very efficient cooling method is available here. Typical (28 mm) HDPE bottle caps with a weight of less than 3 g, molded in a 24-cavity machine powering a 90 t (1,000 kN) machine, cycle in 4.0 seconds, producing 21,600 caps during an hour. We can see how a small adjustment to the flank of the thread can allow the thread to be stripped from the core, instead of having to unscrew the mold. Having a stripped product can result in significant savings in terms of mold cycle, costs, and maintenance.

We can see how a small adjustment to the flank of the thread can allow the thread to be stripped from the core, instead of having to unscrew the mold. Having a stripped product can result in significant savings in terms of mold cycle, costs, and maintenance. https://www.plasticmoulds.net/side-cores.html

Comments

Post a Comment