why bubbles in injection molding

In the process of injection molding, the bubble inside is a serious defect.

Air bubbles in injection molded transparent parts will affect the appearance quality of products. At the same time, it will also reduce the strength of injection molded products.

The bubbles are mainly produced in the process of injection molding:

CASE STUDY:

The curve part of this product is easy to get bubbles, and the solution steps :

Air bubbles in injection molded transparent parts will affect the appearance quality of products. At the same time, it will also reduce the strength of injection molded products.

The bubbles are mainly produced in the process of injection molding:

- The raw materials are not dried enough or air mixed in the raw materials.

- In the injection molding process, the injection speed is too fast, the residual material inside barrel is too much, and the back pressure is too low.

- Poor mold venting and low mold temperature.

How to solve:

- Raw materials should be fully dried.

- Reduce the screw temperature and the temperature of the feeding port.

- Increase the back pressure and reduce the ejection position of screw (more residual material).

- Reduce injection speed and increase mold temperature.

- Increase the injection pressure and time and improve the venting of the mold.

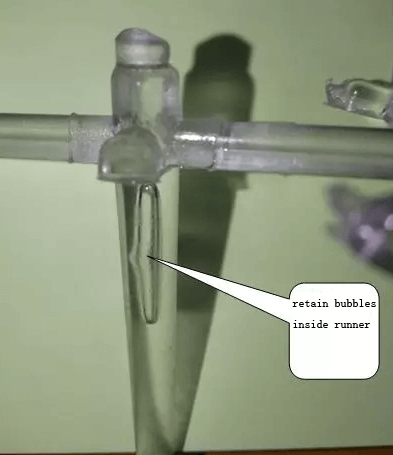

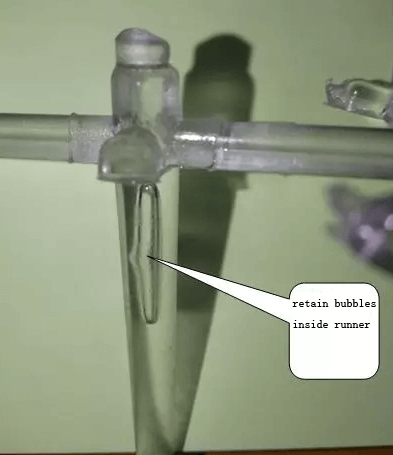

- Retain bubbles on the nozzle material or main runner by changing the injection position for cold runner mold.

CASE STUDY:

The curve part of this product is easy to get bubbles, and the solution steps :

- raw materials should be fully dried. (120℃、4h)

- Properly reduce the screw temperature and the temperature of the nozzle to prevent premature melting and decomposition of PC materials, and air cannot be eliminated.

- Because the gate is small, it is difficult to squeeze bubbles out of the cavity by increasing the holding pressure and time.

- This product is designed with a cold runner , so the best solution is to keep bubbles on the nozzle material. (Increase the injection position of the first stage, reduce the injection speed of the first stage and appropriately increase the back pressure )

Comments

Post a Comment