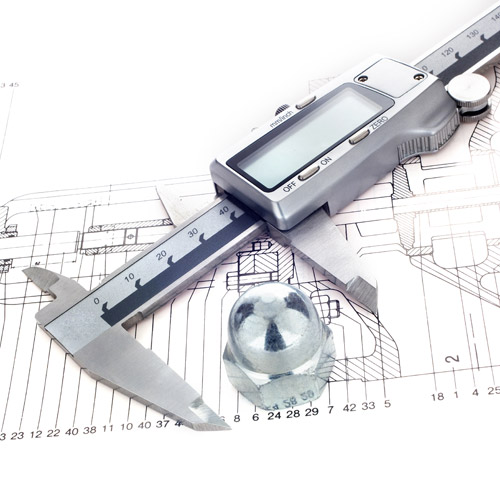

precise machining for tools making

- Get link

- X

- Other Apps

PRECISION MACHINING?

Precision Machining is a process to remove material from a workpiece like plastic mold component during holding close tolerance finishes.

The precision machine has many types, including milling, turning and electrical discharge machining.

A precision machine today is generally controlled using a Computer Numerical Controls (CNC).

Precision machining contributes parts and pieces from space shuttle pencils. Almost all metal products use precision machining, as do many other materials such as plastic and wood.

These machines are operated by specialized and trained machinists. In order for the cutting tool to do its job, it must be moved in directions specified to make the correct cut.

This primary motion is called the “cutting speed.” The workpiece can also be moved, known as the secondary motion of “feed.”

https://www.youtube.com/watch?v=YrbQIN2TBhM&t=609s

Together, these motions and the sharpness of the cutting tool allow the precision machine to operate.

Quality precision machining requires the ability to follow extremely specific blueprints made by CAD (computer aided design) or CAM (computer aided manufacturing) programs like AutoCAD and TurboCAD.

The software can help produce the complex, 3-dimensional diagrams or outlines needed in order to manufacturer a tool, machine or object.

These blueprints must be adhered to with great detail to ensure that a product retains its integrity.

While most precision machining companies work with some form of CAD/CAM programs, they still work often with hand-drawn sketches in the initial phases of a design.

Precision machining is used on a number of materials including steel, bronze, graphite, glass and plastics to name a few.

Depending on the size of the project and the materials to be used, various precision machining tools will be used.

Any combination of lathes, milling machines, drill presses, saws and grinders, and even high-speed robotics may be used.

The aerospace industry may use high velocity machining, while a woodwork tool-making industry might use photo-chemical etching and milling processes.

The churning out of a run, or a specific quantity of any particular item, can number in the thousands, or be just a few.

Precision machining often requires the programming of CNC devices which means they are computer numerically controlled. The CNC device allows for exact dimensions to be followed throughout the run of a product.

WHAT IS LATHING?

A lathe is a tool that rotates the workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working.

Lathes can be used to shape pottery, the best-known design being the potter’s wheel.

Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices.

Ornamental lathes can produce three-dimensional solids of incredible complexity.

The workpiece is usually held in place by either one or two centers, at least one of which can typically be moved horizontally to accommodate varying workpiece lengths.

Other work-holding methods include clamping the work about the axis of rotation using a chuck or collet, or to a faceplate, using clamps or dogs.

Examples of objects that can be produced on a lathe include screws, candlestick holders, gun barrels, cue sticks, table legs, bowls, baseball bats, musical instruments (especially woodwind instruments), crankshafts, and camshafts.WHAT IS MILLING?

Milling is the machining process of using rotary cutters to remove material from a workpiece by advancing (or feeding) the cutter into the workpiece at a certain direction.

The cutter may also be held at an angle relative to the axis of the tool.

Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

It is one of the most commonly used processes for machining custom parts to precise tolerances.

Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill).

After the advent of computer numerical control (CNC), milling machines evolved into machining centers: milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures.

Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs).

The integration of milling into turning environments, and vice versa, begun with live tooling for lathes and the occasional use of mills for turning operations.

This led to a new class of machine tools, multitasking machines (MTMs), which are purpose-built to facilitate milling and turning within the same work envelope.WHAT IS CNC?

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands.

This is in contrast to machines that are manually controlled by hand wheels or levers, or mechanically automated by cams alone.

In modern CNC systems, the design of a mechanical part and its manufacturing program is highly automated.

The part’s mechanical dimensions are defined using computer-aided design (CAD) software, and then translated into manufacturing directives by computer-aided manufacturing (CAM) software.

The resulting directives are transformed (by “post processor” software) into the specific commands necessary for a particular machine to produce the component, and then are loaded into the CNC machine.

Since any particular component might require the use of a number of different tools – drills, saws, etc. – modern machines often combine multiple tools into a single “cell”.

In other installations, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine.

In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD.

As the controller hardware evolved, the mills themselves also evolved.

One change has been to enclose the entire mechanism in a large box as a safety measure, often with additional safety interlocks to ensure the operator is far enough from the working piece for safe operation.

Most new CNC systems built today are 100% electronically controlled.

CNC-like systems are now used for any process that can be described as a series of movements and operations.

These include laser cutting, welding, friction stir welding, ultrasonic welding, flame and plasma cutting, bending, spinning, hole-punching, pinning, gluing, fabric cutting, sewing, tape and fiber placement, routing, picking and placing, and sawing.WHAT IS CNC MACHINING?

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery.

The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot.

In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a machine is directed to cut in more than one direction simultaneously.

The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program.

With a numerical control machine, programs are inputted via punch cards. By contrast, the programs for CNC machines are fed to computers though small keyboards.

CNC programming is retained in a computer’s memory. The code itself is written and edited by programmers.

Therefore, CNC systems offer far more expansive computational capacity.

Best of all, CNC systems are by no means static, since newer prompts can be added to pre-existing programs through revised code.WHAT IS CNC PROGRAMING?

In CNC, machines are operated via numerical control, wherein a software program is designated to control an object.

The language behind CNC machining is alternately referred to as G-code, and it’s written to control the various behaviors of a corresponding machine, such as the speed, feed rate and coordination.

Basically, CNC machining makes it possible to pre-program the speed and position of machine tool functions and run them via software in repetitive, predictable cycles, all with little involvement from human operators.

Due to these capabilities, the process has been adopted across all corners of the manufacturing sector and is especially vital in the areas of metal and plastic production.

For starters, a 2D or 3D CAD drawing is conceived, which is then translated to computer code for the CNC system to execute.

After the program is inputted, the operator gives it a trial run to ensure no mistakes are present in the coding.

In today’s CNC protocols, the production of parts via pre-programmed software is mostly automated.

The dimensions for a given part are set into place with computer-aided design (CAD) software and then converted into an actual finished product with computer-aided manufacturing (CAM) software.

Any given work piece could necessitate a variety of machine tools, such as drills and cutters.

In order to accommodate these needs, many of today’s machines combine several different functions into one cell.

Alternately, an installation might consist of several machines and a set of robotic hands that transfer parts from one application to another, but with everything controlled by the same program.

Regardless of the setup, the CNC process allows for consistency in parts production that would be difficult, if not impossible, to replicate manually.WHAT IS TURNING MACHINING?

Turning machining involves a workpiece (typically metal but could also be wood, plastic or stone) being rotated next to a rotating cutting tool.

Turning machining is generally performed on lathe machines.

There are different types of turning machining including: straight turning, threads, taper turning and external grooving.

In straight turning, the workpiece is rotated while a single cutting tool moves parallel to it.

In tapered turning, a tapered turning attachment is used.

For external grooving turning machining, grooves are cut to specific depths.

The grooves are not removed completely as they are in the parting turning method.

Lathe machines are used to shape materials by rotating the workpiece into a cutting tool.

There are three types of lathe machines: engine lathe, turret lathe and special purpose lathes.

Lathe machines can range in size from small and portable to big, floor mounted machines.WHAT ARE CNC LATHE MACHINES?

A CNC Lathe Machine is controlled by a computer. It is an automated method of generating a variety of shapes, features and dimensions while holding close tolerances.

Lathe machines date back to ancient Egypt.

Over the years, lathe machines have transitioned from being made of wood to metal. Today’s lathe machines are usually operated by computers.

In lathe machines, pieces are cut in a circular direction with indexable tools.

With CNC technology, the cuts employed by lathes are carried out with precision and high velocity.

CNC lathes are used to produce complex designs that wouldn’t be possible on manually run versions of the machine. Overall, the control functions of CNC-run mills and lathes are similar.

As with the former, lathes can be directed by G-code or unique proprietary code. However, most CNC lathes consist of two axes — X and Z.WHAT IS A MILLING MACHINE?

CNC mills are capable of running on programs comprised of number- and letter-based prompts, which guide pieces across various distances.

The programming employed for a mill machine could be based on either G-code or some unique language developed by a manufacturing team.

Basic mills consist of a three-axis system (X, Y and Z), though most newer mills can accommodate three additional axes.

A milling machine is used to cut and shape solid materials.

A milling machine can be vertical or horizontal, based on the orientation of the spindle.

Both the workpiece and milling cutter move, controlled manually, mechanically or through a digital computer numerical control (CNC Milling Machine).

Milling machines generally use cutting fluid to wash away excess material and cool and lubricate the metal. The waste material removed is called chips.

The workpiece and cutting piece can be controlled down to .001 inches. Both simple and complex cuts are made with milling machines from keyway cutting to diesinking.WHAT IS A CNC MILLING MACHINE?

A CNC Milling Machine is controlled by a computer. It is generally used with a vertical or horizontal milling machine and can move the spindle along the Z-axis.

The first CNC machines, then called numerically controlled (NC) machines, were built in the 1940s and 1950s and followed points on punched tape to direct the motors to move.

A CNC machine today works with computer-aided design (CAD) and computer-aided manufacturing (CAM) programs and is highly automated.WHAT IS PLASMA CUTTERS?

Involves cutting a material using a plasma torch. Commonly used to cut steel and other metals, but can be used on a variety of materials.

In this process, gas (such as compressed air) is blown at high speed out of a nozzle; at the same time, an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma.

The plasma is sufficiently hot to melt the material being cut and moves sufficiently fast to blow molten metal away from the cut.WHAT IS ELECTRIC DISCHARGE MACHINING?

(EDM), also known as spark machining, spark eroding, burning, die sinking, or wire erosion, is a manufacturing process in which a desired shape is obtained using electrical discharges (sparks).

Material is removed from the workpiece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric fluid and subject to an electric voltage.

One of the electrodes is called the tool electrode, or simply the “tool” or “electrode,” while the other is called the workpiece electrode, or “workpiece.”WHAT IS MULTI SPINDLE MACHINES?

Type of screw machine used in mass production. Considered to be highly efficient by increasing productivity through automation.

Can efficiently cut materials into small pieces while simultaneously utilizing a diversified set of tooling. Multi-spindle machines have multiple spindles on a drum that rotates on a horizontal or vertical axis.

The drum contains a drill head which consists of a number of spindles that are mounted on ball bearings and driven by gears.

There are two types of attachments for these drill heads, fixed or adjustable, depending on whether the center distance of the drilling spindle needs to be varied.WHAT IS WIRE EDM?

Also known as wire cutting EDM, wire burning EDM, or traveling wire EDM, this process uses spark erosion to machine or remove material from any electrically conductive material, using a traveling wire electrode.

The wire electrode usually consists of brass or zinc-coated brass material.

Wire EDM allows for near 90 degree corners and applies very little pressure on the material.

Since the wire is eroded in this process, a wire EDM machine feeds fresh wire from a spool while chopping up the used wire and leaving it in a bin for recycling.WHAT IS SINKER EDM?

Also called cavity type EDM or volume EDM, sinker EDM consists of an electrode and workpiece submerged in oil or another dielectric fluid.

The electrode and workpiece are connected to a suitable power supply, which generates an electrical potential between the two parts.

As the electrode approaches the workpiece, dielectric breakdown occurs in the fluid forming a plasma channel and small spark jumps.

Production dies and molds are often made with sinker EDM.

Some materials, such as soft ferrite materials and epoxy-rich bonded magnetic materials are not compatible with sinker EDM as they are not electrically conductive.WHAT IS WATER JET CUTTER?

Also known as a waterjet, is a tool capable of slicing into metal or other materials (such as granite) by using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance, such as sand.

It is often used during fabrication or manufacture of parts for machinery and other devices.

Waterjet is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods.

It has found applications in a diverse number of industries from mining to aerospace where it is used for operations such as cutting, shaping, carving, and reaming.

- Get link

- X

- Other Apps

Comments

Post a Comment