How to store and maintain the plastic mold

Storing Molds

During downtime, plastic molds are generally removed from the molding press and put into some kind of maintenance.

The mold warehouse usually has s few heavy-duty steel shelves where the molds are positioned onto ,and labeled for identity.

Generally, the mold contains particular identity engraved on perhaps 2 adjacent walls so it's easily observable, and the shelf comes with an id label attached to each place that matches the mold identity.

This assists you to hold everything in arrangement and prepare for following jobs.

The sort of mold maintaining in the course of storage relies on how much time required.

Long-term storing needs a heavy-duty treatment that generates a thicker layer of protective substance on the mold.

But this layer is tough to clear out.

A significantly lesser layer does apply for short-term holding.

Short-term storage

Short-term storing can be regarded as holding which will be for less than a day roughly, totally about Four weeks.

For this particular kind of storing, the mold should be maintained completely ,then sprayed by a neutralizer to clear out any kind of chemicals found from finger prints or any other acid-producing products.

Next, a layer of corrosion preventive ought to be employed, a simple coating for several days storing and a moderate coating for about 4 weeks holding.

The waterlines needs to be cleaned dry with pressurized air flow then applied with a corrosion preventive.

The surface of the mold needs to be cleaned and dispersed gently with corrosion preventive or mild grease.

The sprue bushing must be applied with mild grease to protect its interior area.

Long-term storage

Long-term storing serves as a warehousing enduring above Four weeks at some point.

When it is uncertain how much time a mold come in storage area, presume it will likely be for over 4 weeks.

By doing this the mold will be guaranteed to be secured, no matter the span of time.

With regard to long-term safe-keeping, the mold needs to be taken aside and checked out.

Destroy needs to be mended .The mold elements and base needs to be completely maintained, neutralized, put back together, and sprayed in and out with a thicker layer of corrosion preventive.

It needs to be presumed that every measures described in short-term storing additionally employ here.

Nevertheless, the waterlines needs to be rich in protecting foam which can be found from mold base stores.

This will stop the mold from corroding internally. The foam corrosion protective materials are of much more duty and more durable compared to basic corrosion preventive substance.

A few businesses demand that all long-term molds get enclosed in plastic film prior to being positioned on the storing stand. Nevertheless, this might bring about caught moisture build-up or condensation.

Usually, it is advisable to get dried air disbursing throughout the molds to assist reduce corrosion.

It is safe and sound to mention that any kind of mold will demand some fix for problems taking place in the course of the employ or storing. The harder it is utilized, or the more time it is kept, the greater damage will happen.

Incorrect maintenance is the key reason behind injury to a mold.

Mold deterioration restoration can vary from being an easy task to that of terrific challenges, with respect to the level and sort of injury.

For maintenance and restoration requirements, it is recommended that molds be developed to ensure that weak elements (for example entrance areas) can easily be changed or mended.

You can do this by insert and laminated design.

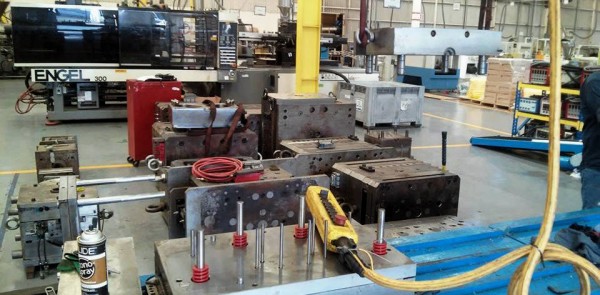

[caption id="attachment_3461" align="alignnone" width="800"]

plastic molding company[/caption]

plastic molding company[/caption][divider_top]

Maintenance

Maintenance purpose: In order to ensure the normal production of the mold, reduce failed production and solve quality problems, and at the same time extend the life of the mold.

Before Production:

Remove the dust, oil and rust of the mold on the surface before installing it on the injection molding machine.

Use air hose or rag, detergent or alcohol (alcohol for mirror mold) to clean the oil on the mold surface.

Check the plastic mold's cooling channel for foreign material to ensure water passage operation successfully.

Check the sprue for the damage, and whether there are any remaining foreign material. If necessary, clean it up.

Moving parts: such as ejector pins, springs, hydraulic cylinders, sliders, check for the rust, bending, or fracture, and the smooth movement .

During Production:

The molds installed on the machine should be inspected and maintained daily.

Check the mold's guide pins, guide sleeves, and sliders for damage and foreign material , and grease them once a day.

Clean the mold parting surface for the foreign material or oil stain on the venting groove, and clean them with air hose or rag, detergent or alcohol once a day.

After Production:

Inspect each part of the mold for damage.

Clean the greasy dirt on the parting surface and the debris in the mold cavity, and spray with anti-rust oil.

Blow off the water remaining in the cooling water channel.

Precautions:

Always wear labor protection supplies when maintaining the mold.

Overweight objects must be operated with a crane.

It is strictly prohibited to lift the mold directly by hand to prevent injury.

The rust prevention of the mold is necessary. After the mold is maintained, the rust prevention action of the mold should be taken. The remaining water in the water channel must be blown out with an air hose.

Too much lubricating oil does not bring better lubricating effect, just the right amount is enough.

When the mold is installed and maintained, pay attention to the numbers and instructions on the inserts and other components.

Do not install them incorrectly. Check whether the screws are complete and tighten them diagonally when installing the screws.

click for more on complete plastic mold maintenance.

[…] the consumer desires the molder to go on having the exercise-free mold’ storage, rates may be […]

ReplyDelete