How to choose mould steel

The choice of mould steel is of great importance if the mould is to function effectively.

When plastic is molded, due to molecular stretching and shearing, residual stress is left in the product, which causes the product to warp and even crack.

Residual stress is also generated during the machining of the mold steel. This residual stress also causes the mold to deform or even crack.

The prime function of any mould steel must be that of meeting the service requirements imposed upon it.

Moulding requirements vary,e.g. from simple prototype work undertaken on soft aluminium construction moulds, to fully hardened alloy steel volume production moulds moulding to close dimensional tolerances.

In order to avoid costly long-term mistakes, the plastic mould application must be thoroughly investigated and fully understood before a selection decision can be made.

Once decided upon,the selected material should be written into the tooling specification for future procurement purposes.

The use of a tooling specification laying out the mould requirements prior to tool quotation or construction greatly reduces the risk of fundamental mistakes being made at the toolmaking stage.

https://www.youtube.com/watch?v=7E__zqy6xcw

The mould has high requirements for steel. Whether the steel is properly selected has a great influence on the service life, processability and precision of the mould.

The requirements vary depending on the structure of the mould, the service life of the mould, the plastic used for moulding, and the performance, appearance, and dimensional accuracy of the moulded product.

A mould steel should possess qualities or attributes relevant to the intended application.

For general purpose moulding applications, the principal steel attributes are listed and explained below.

(a) High core strength.

As a result of the service conditions encountered during injection moulding, i.e. relatively high compressive cyclic loadings, the material core strength is of relevance to the mould designer.

The material must be able to withstand high compressive loads without cracking or splitting.

(b) Good wear resistance.

Mould tools are subject to considerable wear from many sources, which include:

Wear resistance may be imparted to a mould tool steel by various means,usually by hardening the material or the addition of property modifying alloying elements. The choice of which method depends on the material in question.

Wear resistance and abrasion resistance are the most important properties of mould steel, which have considerable influence on the post-processing of mould life, precision maintenance, overflow removal, etc.

Wear resistance varies according to the amount of alloy elements and the presence of internal stress.

Wear resistance is generally proportional to hardness.

Therefore, the hardness of the cavity surface increases, which can solve the problem of wear resistance.

Glass fibers are often added to increase the strength and wear resistance. In addition, metal fiber can also be added to the plastic to get conductive plastic to protect against radio wave interference.

There are also plastic magnets compounded with ferrous salt magnets.

The biggest problem of these additives in molding is that the friction of various fibers in the composite material in the cavity is intensified, causing the wear of the mold cavity and affecting the dimensional accuracy of the products.

Therefore, in order to prolong the life of the mould, steel with good wear resistance must be used.

(c) Excellent surface finish.

A good serviceable surface finish is of the utmost importance, especially for core and cavity components.

The intended material should be capable of sustaining a good long-term surface finish without the additional requirement of polishing between production runs.

As with wear resistance,the material’s surface hardness and composition have the greatest influence on its finishing properties.

For the injection mould, the surface roughness of the mould cavity directly affects the surface of the product.

For transparent PC products, the surface of the cavity and core requires mirror polishing, and the polishability of the mold steel becomes a major problem. steel polishing performance:

For mirror polishing of molds, the following polishing techniques must be observed:

(d) Dimensional stability.

The cyclic loading nature of the injection moulding process subjects the mould materials to considerable levels of stress and elastic deformation.

The ideal mould material should possess sufficient strength and durability to resist permanent deformation but sufficient ductility to resist cracking and impact loadings.

For this purpose, many grades of mould steel, especially steel alloys, have been developed to fulfil the above requirements.

(e) Machinability

The processing of injection mold components can be divided into machining (such as lathe, milling, numerical control milling, grinding, fitter, engraving, polishing, etc.), electrical processing (such as electrode, wire cutting, etc.) and casting processing.

The selection of mould steel must consider both the service life and the machining of the die.

Consider the steel material from the machinability, it is best to use the low hardness steel that can be machined conventionally during cutting, but this steel is difficult to ensure the service life of the mold and the accuracy of the cavity.

Therefore, in actual work, the pre-hardened (quenched and tempered) steel with good machinability is often used as the mould insert.

For precision and long-life molds, nitriding treatment can be done on the surfaces of cores and cavities to improve the wear resistance.

(f) Corrosion resistance

Halogen-containing plastic material such as polyvinyl chloride (PVC) and polyacetal often releases corrosive gases to damage the mould.

The best way is to use corrosion resistant steel, such as S136H, PAK90, etc.

In addition, beryllium copper is also a good corrosion resistant steel material.

In order to make the mould corrosion resistant, sometimes chrome plating is also done in the cavity, but hard chrome plating has the following disadvantages:

(1) Weaker corrosion resistance;

(2) The plating layer will have pinholes or cracks . Due to the local electrodes affect, it will lead to the corrosion of the steel and the plating layer, causing the peeling of the chrome layer.

The term alloy steel describes a steel material which contains other alloying elements in addition to carbon which have been added to deliberately modify the properties of the steel.

Mould tool steels contain quantities of specific elements which combine with the steel to improve the material’s intended application properties.

Typical alloying elements used in mould tool steels and their contributing effects upon the alloy produced are listed below.

The alloying elements and their addition percentages vary according to the different steel manufacturers and the intended applications.

Choosing a steel for a mould is a difficult business, especially for the beginner.

Most steel producers manufacture and supply mould tool steels bearing their own trade names and designation code numbers.

Within the steel industry, various organisations and institutions exist which are responsible for the quality and national standard of steels. Some of the more prominent are:

American Iron and Steel Institute (AISI);

Swedish Standardisering Kommission (ISI);

various European standards institutes,e.g. DIN and BS 970.

Internationally the AISI designation has been adopted and most of the major steel manufacturers give equivalent designation code numbers.

An AISI code reads,for example, AISI D3,where D denotes the class of steel, and 3 denotes the grade of steel within the class. In this case, AISI D3 is a high carbon content, high chromium steel used for mould core or cavity components.

As a result of the demanding requirements of mould steels,alloy steels are commonly used during the construction of mould tools and dies .

***Carburizing is a surface hardening process which involves changing the composition of the steel’s surface layers. The process increases the steel's surface carbon content from less than 0.2% to about 0.7-0.8%. The resultant steel after quenching treatment has a harder surface layer (e.g. 60 Rc) and a softer, more ductile inner core (e.g. 20 Rc). The depth of the carburized ease layer is dependent on time,temperature and the carburizing medium employed.

Other surface hardening treatments exist which could also be employed,such as nitriding and carbon nitriding. For steels with a carbon content of over 0.4-0.7%, selective surface heat treatments are usually employed, e.g. flame hardening or induction hardening.***

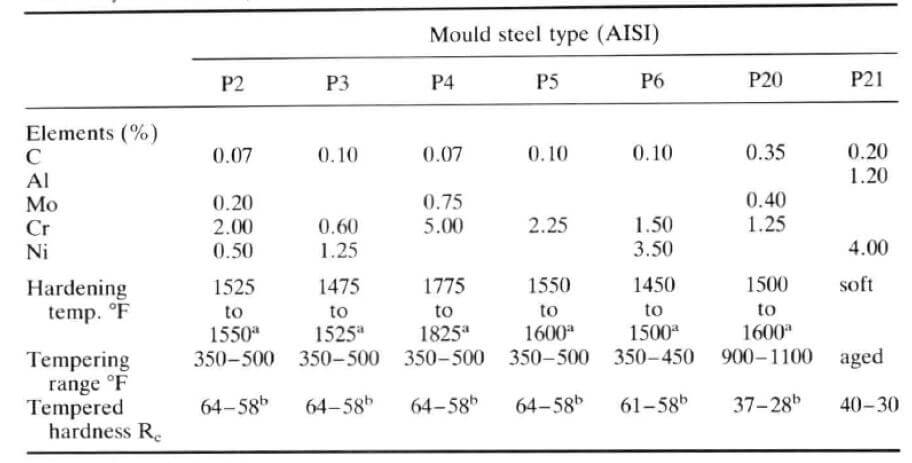

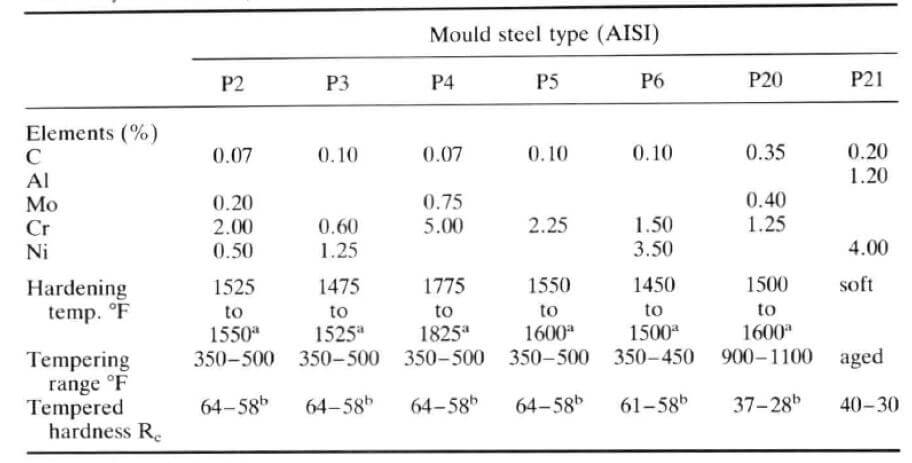

The AISI class designation for mould steels is the letter "P",for general purpose mould tool applications. The table above shows composition and heat treatment details for AISI P class steels.

The AISI P range of steel grades possesses relatively good machining properties due to the alloy compositions. Machining processes such as spark erosion and all the usual metal cutting processes can be employed during tool manufacture.

As a result of the Ni-Cr content of the steel,a good surface finish is achievable using various polishing and finishing techniques. The steels corrosion resistance is also improved compared with a plain carbon steel.

While the AISI P range of steels represents a reasonable general purpose steel choice for moulding applications, extremes of application requirement will always exist.

In such cases, a more specialised steel should be selected,the properties of which reflect the use application intended. The following examples have been chosen to demonstrate the service conditions in which a specialised steel type/grade may be selected.

[table id=14 /]

When plastic is molded, due to molecular stretching and shearing, residual stress is left in the product, which causes the product to warp and even crack.

Residual stress is also generated during the machining of the mold steel. This residual stress also causes the mold to deform or even crack.

The prime function of any mould steel must be that of meeting the service requirements imposed upon it.

Moulding requirements vary,e.g. from simple prototype work undertaken on soft aluminium construction moulds, to fully hardened alloy steel volume production moulds moulding to close dimensional tolerances.

In order to avoid costly long-term mistakes, the plastic mould application must be thoroughly investigated and fully understood before a selection decision can be made.

Once decided upon,the selected material should be written into the tooling specification for future procurement purposes.

The use of a tooling specification laying out the mould requirements prior to tool quotation or construction greatly reduces the risk of fundamental mistakes being made at the toolmaking stage.

https://www.youtube.com/watch?v=7E__zqy6xcw

Mould steel requirements

The mould has high requirements for steel. Whether the steel is properly selected has a great influence on the service life, processability and precision of the mould.

The requirements vary depending on the structure of the mould, the service life of the mould, the plastic used for moulding, and the performance, appearance, and dimensional accuracy of the moulded product.

A mould steel should possess qualities or attributes relevant to the intended application.

For general purpose moulding applications, the principal steel attributes are listed and explained below.

(a) High core strength.

As a result of the service conditions encountered during injection moulding, i.e. relatively high compressive cyclic loadings, the material core strength is of relevance to the mould designer.

The material must be able to withstand high compressive loads without cracking or splitting.

(b) Good wear resistance.

Mould tools are subject to considerable wear from many sources, which include:

- (i) the polymer itself;

- (ii) the mould ejection system;

- (iii) the wearing action of shut-off faces;

- (iv) abuse during cycling and shut shots.

Wear resistance may be imparted to a mould tool steel by various means,usually by hardening the material or the addition of property modifying alloying elements. The choice of which method depends on the material in question.

Wear resistance and abrasion resistance are the most important properties of mould steel, which have considerable influence on the post-processing of mould life, precision maintenance, overflow removal, etc.

Wear resistance varies according to the amount of alloy elements and the presence of internal stress.

Wear resistance is generally proportional to hardness.

Therefore, the hardness of the cavity surface increases, which can solve the problem of wear resistance.

Glass fibers are often added to increase the strength and wear resistance. In addition, metal fiber can also be added to the plastic to get conductive plastic to protect against radio wave interference.

There are also plastic magnets compounded with ferrous salt magnets.

The biggest problem of these additives in molding is that the friction of various fibers in the composite material in the cavity is intensified, causing the wear of the mold cavity and affecting the dimensional accuracy of the products.

Therefore, in order to prolong the life of the mould, steel with good wear resistance must be used.

(c) Excellent surface finish.

A good serviceable surface finish is of the utmost importance, especially for core and cavity components.

The intended material should be capable of sustaining a good long-term surface finish without the additional requirement of polishing between production runs.

As with wear resistance,the material’s surface hardness and composition have the greatest influence on its finishing properties.

For the injection mould, the surface roughness of the mould cavity directly affects the surface of the product.

For transparent PC products, the surface of the cavity and core requires mirror polishing, and the polishability of the mold steel becomes a major problem. steel polishing performance:

- No sand hole;

- No scratches;

- Very few non-metallic materials;

- Homogeneous structure (no segregation, etc.)

- Fine crystal grain size (no coarse grain);

- Appropriate hardness;

- Appropriate mechanical properties.

For mirror polishing of molds, the following polishing techniques must be observed:

- Polishing paste with high polishing ability

- Uneven polishing power will produce an orange peel surface;

- The abnormal layer of deterioration due to electrode processing and wire cutting can be completely removed by grinding.

(d) Dimensional stability.

The cyclic loading nature of the injection moulding process subjects the mould materials to considerable levels of stress and elastic deformation.

The ideal mould material should possess sufficient strength and durability to resist permanent deformation but sufficient ductility to resist cracking and impact loadings.

For this purpose, many grades of mould steel, especially steel alloys, have been developed to fulfil the above requirements.

(e) Machinability

The processing of injection mold components can be divided into machining (such as lathe, milling, numerical control milling, grinding, fitter, engraving, polishing, etc.), electrical processing (such as electrode, wire cutting, etc.) and casting processing.

The selection of mould steel must consider both the service life and the machining of the die.

Consider the steel material from the machinability, it is best to use the low hardness steel that can be machined conventionally during cutting, but this steel is difficult to ensure the service life of the mold and the accuracy of the cavity.

Therefore, in actual work, the pre-hardened (quenched and tempered) steel with good machinability is often used as the mould insert.

For precision and long-life molds, nitriding treatment can be done on the surfaces of cores and cavities to improve the wear resistance.

(f) Corrosion resistance

Halogen-containing plastic material such as polyvinyl chloride (PVC) and polyacetal often releases corrosive gases to damage the mould.

The best way is to use corrosion resistant steel, such as S136H, PAK90, etc.

In addition, beryllium copper is also a good corrosion resistant steel material.

In order to make the mould corrosion resistant, sometimes chrome plating is also done in the cavity, but hard chrome plating has the following disadvantages:

(1) Weaker corrosion resistance;

(2) The plating layer will have pinholes or cracks . Due to the local electrodes affect, it will lead to the corrosion of the steel and the plating layer, causing the peeling of the chrome layer.

Alloy steel

The term alloy steel describes a steel material which contains other alloying elements in addition to carbon which have been added to deliberately modify the properties of the steel.

Mould tool steels contain quantities of specific elements which combine with the steel to improve the material’s intended application properties.

Typical alloying elements used in mould tool steels and their contributing effects upon the alloy produced are listed below.

| Element | Typical amount (%) | Main effect on properties | ||||

| Aluminium A1 | 0.5-1.3 | Aids nitriding | ||||

| Chromium Cr | 0.5-2.0 | Increases hardenability and improves corrosion resistance | ||||

| Manganese Ma | 0.2-0.4 | Acts with sulphur to reduce brittleness | ||||

| Molybdenum Mo | 0.1-0.5 | Aids heat treatment and improves strength and toughness | ||||

| Nickel Ni | 0.3-6.5 | Increases hardenability and improves strength and toughness | ||||

| Silicon Si | 0.2-2.0 | Increases hardenability and limits oxygen in steel making | ||||

| Tungsten W | 1.0-18.0 | Improves hardness at higher working temperatures | ||||

The alloying elements and their addition percentages vary according to the different steel manufacturers and the intended applications.

Choosing a steel for a mould is a difficult business, especially for the beginner.

Most steel producers manufacture and supply mould tool steels bearing their own trade names and designation code numbers.

Within the steel industry, various organisations and institutions exist which are responsible for the quality and national standard of steels. Some of the more prominent are:

American Iron and Steel Institute (AISI);

Swedish Standardisering Kommission (ISI);

various European standards institutes,e.g. DIN and BS 970.

Internationally the AISI designation has been adopted and most of the major steel manufacturers give equivalent designation code numbers.

An AISI code reads,for example, AISI D3,where D denotes the class of steel, and 3 denotes the grade of steel within the class. In this case, AISI D3 is a high carbon content, high chromium steel used for mould core or cavity components.

General purpose mould steels

As a result of the demanding requirements of mould steels,alloy steels are commonly used during the construction of mould tools and dies .

***Carburizing is a surface hardening process which involves changing the composition of the steel’s surface layers. The process increases the steel's surface carbon content from less than 0.2% to about 0.7-0.8%. The resultant steel after quenching treatment has a harder surface layer (e.g. 60 Rc) and a softer, more ductile inner core (e.g. 20 Rc). The depth of the carburized ease layer is dependent on time,temperature and the carburizing medium employed.

Other surface hardening treatments exist which could also be employed,such as nitriding and carbon nitriding. For steels with a carbon content of over 0.4-0.7%, selective surface heat treatments are usually employed, e.g. flame hardening or induction hardening.***

The AISI class designation for mould steels is the letter "P",for general purpose mould tool applications. The table above shows composition and heat treatment details for AISI P class steels.

The AISI P range of steel grades possesses relatively good machining properties due to the alloy compositions. Machining processes such as spark erosion and all the usual metal cutting processes can be employed during tool manufacture.

As a result of the Ni-Cr content of the steel,a good surface finish is achievable using various polishing and finishing techniques. The steels corrosion resistance is also improved compared with a plain carbon steel.

While the AISI P range of steels represents a reasonable general purpose steel choice for moulding applications, extremes of application requirement will always exist.

In such cases, a more specialised steel should be selected,the properties of which reflect the use application intended. The following examples have been chosen to demonstrate the service conditions in which a specialised steel type/grade may be selected.

[table id=14 /]

[…] plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the […]

ReplyDelete