opportunities for the production design engineer

opportunities for the production design engineer

Production design work in both the areas of product and process design will provide a rewarding lifetime job. The engineer knows that his work will make possible better products for more people at less cost. He will have rewarding personal contacts with the shop, sales, and service forces, and with his fellow engineers, research workers, designers, shop supervisors, and managers. The field of production design has come to offer some of the best opportunities afforded in industry. It may involve just a routine operation wherein apparatus is designed or modified to suit customer requirements, or it may be a comprehensive program including —in addition to design —sales analysis, research, invention, experimentation, and field tests which result in the development of a product. It may include the development of special equipment for the manufacturer of a product; the training of operators, construction and service men, and salesmen; and co-operation in the promotion of sales through advertising and demonstration.

Production design positions may involve the development or improvement of a line of products or a part, such as the engine, chassis or body of an automobile. These improvements are accumulated and at periodic intervals new designs are introduced. Tools, equipment, and buildings must then be arranged for the production of the new design or new product.

In some instances, product design may involve the creation of large integrated units, such as an entire plant producing chemicals, pharmaceuticals, gas, or energy. For example, a steel rolling mill may be controlled numerically from the heating of the billet through the many stages of rolling until the final finished sheet is made. The adjustments of speed, size, and heat are all made automatically. The refinement of petroleum products is completely automated in many locations. Power plants are started up automatically, steam is generated, the turbine is brought up to speed and the generator develops the power without the aid of an operator.

Today, many components are made by processing the raw material into the final product without a hand touching the controls of the processing equipment. As American industry becomes more and more automated, the production design engineer will find greater demand for his highest skills. In the very small plant, all the work related to designing a product and planning its production may be the responsibility of one individual. As a plant grows, more product lines may be taken on and these immediately introduce the use of new and different mate rials and processes. This usually results in two separate activities: the design of the product and the design or planning of the production of the product. As an organization continues to grow, the size of these two activities increases and they become more decentralized. Within the product design group, functional specialists, such as the vibration engineer and the electrical designer, have come into being. These may be further specialized by application, such as automotive, aircraft, power, or appliance. This same specialization will prevail in the process design section. Thus there may be a machine shop planner, inspection planner, finishing planner, joining planner, or assembly planner.

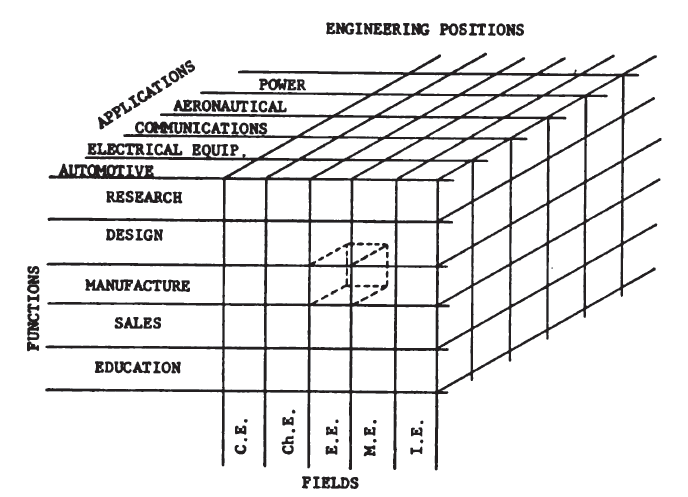

Today, many components are made by processing the raw material into the final product without a hand touching the controls of the processing equipment. As American industry becomes more and more automated, the production design engineer will find greater demand for his highest skills. In the very small plant, all the work related to designing a product and planning its production may be the responsibility of one individual. As a plant grows, more product lines may be taken on and these immediately introduce the use of new and different mate rials and processes. This usually results in two separate activities: the design of the product and the design or planning of the production of the product. As an organization continues to grow, the size of these two activities increases and they become more decentralized. Within the product design group, functional specialists, such as the vibration engineer and the electrical designer, have come into being. These may be further specialized by application, such as automotive, aircraft, power, or appliance. This same specialization will prevail in the process design section. Thus there may be a machine shop planner, inspection planner, finishing planner, joining planner, or assembly planner.Engineering positions in industry are classified according to the following:

- Fields (Such as industrial, mechanical, electrical, civil, and chemical).

- Functions (Such as research, manufacturing, sales, education and training; and their subdivisions, for example, development, design, application, time study, methods, tool, maintenance, and service).

- Applications (Such as electrical manufacturing, aeronautical, communications, power, and railroad).

Figure 1. illustrates the various areas in which engineers are utilized. For example, the dotted cube represents electrical engineering positions in the manufacturing function of the automotive industry. There may be hundreds of positions within the dotted cube and all other cubes indicated on the diagram. Production design is responsible for the co-operative efforts of the functional design department and the manufacturing engineering department. It serves as the means whereby barriers of misunderstanding and lack of knowledge as to processes, materials, and the functions of the product are overcome. There has been a definite trend recently toward the realization of the need of departmental co-operation, and also for organization and exchange of pertinent information. The work of production design is being recognized.

Comments

Post a Comment